Efficient application of line laser profile sensors for metal part inspection

With the continuous progress of industrial manufacturing technology, accurate measurement of the size and shape of metal parts has become more and more important. As an advanced inspection technology, POMEAS line laser profile sensors show great potential in the application of metal parts due to their high efficiency and accuracy.

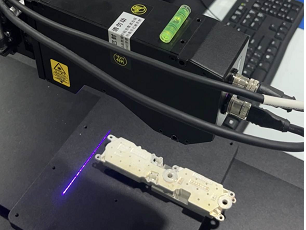

POMEAS line laser contour sensors utilize advanced laser scanning technology to quickly scan the contour of irregular metal parts. This sensor achieves precise measurement of the object's contour by emitting a line laser beam to the surface of the object under test and receiving the reflected light signal back. During the inspection of metal parts, this technology accurately captures every small change in the contour, ensuring accurate and reliable measurement results.

In addition to contour scanning, POMEAS line laser contour sensors can also measure important parameters such as height, flatness, thickness and flatness of metal parts. These parameters are critical for quality control and performance evaluation of metal parts. Through accurate measurement, the sensors are able to detect defects and problems that may exist in the production process of metal parts, such as dimensional deviations, surface unevenness, etc., thus ensuring that the quality of metal parts meets the design requirements.

In the manufacturing and processing of metal parts, the application of POMEAS line laser profile sensors not only improves the efficiency and accuracy of measurement, but also greatly simplifies the inspection process. While traditional measurement methods often require the use of multiple tools and equipment, line laser contour sensors are able to measure multiple parameters in a single pass, saving time and labor costs.

In addition, POMEAS line laser profile sensors are characterized by high stability and repeatability. Even under long hours of continuous operation, the sensor maintains stable measurement performance, ensuring consistency and accuracy in every measurement. This is important for mass production and quality control of metal parts.

The POMEAS line laser contour sensor demonstrates excellent performance and benefits in metal part applications. It can not only quickly and accurately measure the contour and key dimensional parameters of metal parts, but also greatly improve the efficiency and accuracy of measurement. With the continuous development of industrial manufacturing technology, it is believed that POMEAS line laser contour sensors will be widely used and promoted in more fields.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION