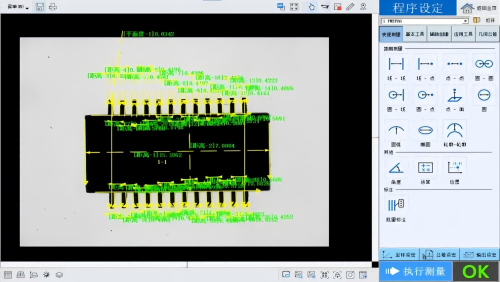

Image Meter (Flash Meter) Application pin angle measurement program

In modern manufacturing, every step to ensure product quality is crucial, especially for precision components, where any small dimensional deviation or shape irregularity may affect the performance and reliability of the final product. Therefore, an efficient and accurate sample inspection system becomes an indispensable tool. In this paper, we will introduce a multi-dimensional sample inspection solution based on POMEAS image measuring instrument (flash meter), which covers several key inspection contents such as length and width inspection, pin angle and distance inspection, and flatness inspection, aiming to provide a comprehensive and flexible inspection solution for enterprises.

Inspection Content:

1. Length and width inspection: This section focuses on the length and width dimensions of the samples. With the high precision imaging technology of POMEAS image measuring instrument, it can quickly capture the edges of the samples and realize millimeter-level or even finer size measurement to ensure that the samples' dimensions are in accordance with the design requirements.

2. Pin Corner Distance Inspection: For three different types of samples, 1-3 samples are randomly selected from each box for measurement. The purpose of this step is to verify the relative position of the pin corners to ensure that they can be accurately aligned during assembly or use to minimize assembly errors. The POMEAS image measuring machine is able to automatically recognize and measure the exact distance between pin corners through advanced image processing algorithms.

3. Flatness Inspection: Flatness is a key indicator of whether a pin corner is flat or not. During the inspection process, the instrument measures the height distance of the pin angle to an absolute plane as a reference. If there is no significant difference between all measured pin corners at the same horizontal height, the pin will be judged to have passed the test. This function relies on the high precision 3D measurement capability of POMEAS image measuring instruments to ensure the accuracy and reliability of the inspection results.

Test Results:

Detection Program Advantage:

- Multi-functional Measurement: POMEAS Image Measuring Instrument is not only limited to the above inspection contents, but also can measure length, width, diameter, angle, segment difference, height, shape tolerance, contour, roughness, and other parameters, to meet diversified inspection needs.

- Intelligent integration: The instrument supports connection with MES (Manufacturing Execution System) to realize real-time uploading and analysis of production data, and at the same time, it can communicate with robots, which has a high degree of automation and improves inspection efficiency.

- Flexible Report Output: Inspection results can be output to Word, TXT, EXCEL and other file formats, and the report format can be customized according to customer needs, facilitating data management and analysis.

- High precision and flexibility: Within the field of view of the instrument, the product can be placed arbitrarily without affecting the measurement precision. The programmable light source can be freely switched according to inspection needs, adapting to samples of different materials and surface conditions.

- Ease of use: the instrument interface design is simple and intuitive, easy to operate, and can be started after a short period of training, and the measurement results between different operators are highly consistent, which ensures the consistency and repeatability of the test.

POMEAS Image Measuring Instrument provides strong support for enterprises' sample inspection work with its comprehensive inspection capability, highly intelligent integration, flexible report output, high-precision measurement and easy operation. This efficient and accurate multi-dimensional sample testing solution not only improves the efficiency of product quality control, but also lays a solid foundation for the company's sustainable development and market competitiveness.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com