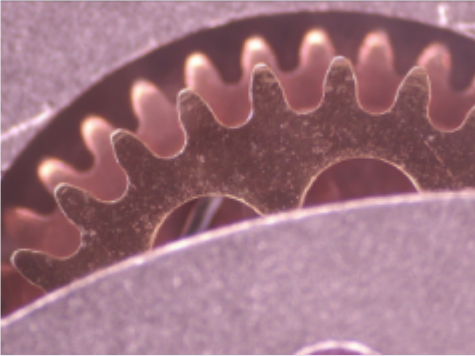

In automotive and industrial instrumentation, accurate inspection of dial gears is a critical step to ensure proper operation and accurate display of the instrument. However, dial gear inspection faces many difficulties, as follows:

① Tiny size: dial gears are usually small in size and compact in structure, which makes it difficult to accurately align and adjust the inspection equipment during the inspection process, increasing the processing and measurement errors.

② High precision requirements: the meshing accuracy of the gear directly affects the accuracy of the instrument display, so the gear tooth shape, tooth pitch, tooth height and other parameters of the detection of high precision requirements.

③ Complicated operation: traditional detection methods often need to manually adjust the focus and observation angle, which is not only time-consuming, but also easy to introduce human error.

④ Influence of environmental conditions: dial gears are usually located inside the instrument, the detection of light, dust and other environmental factors need to be taken into account to ensure the accuracy of the test results.

Solution:

In order to meet the requirements of dial gears inspection accuracy and small size, POMEAS AF microscope is designed with integrated body and a full set of self-developed optical system, which has the functions of light source switching, continuous zoom, and autofocus, etc., and provides an efficient and precise solution for the inspection of dial gears.

AF technology: POMEAS AF microscope adopts advanced AF technology, which eliminates the need to manually adjust the focus, and is able to keep the observation position in focus in real time, greatly improving the inspection efficiency and accuracy.

High Definition Imaging: Equipped with a high resolution camera and optical system, POMEAS AF microscope is able to clearly present the fine structure of dial gears, including key parameters such as tooth shape, tooth pitch, tooth height, to meet the demand for high precision inspection.

Continuous zoom function: With the continuous zoom lens, POMEAS AF microscopes are able to quickly adjust the magnification to meet the inspection needs of different sizes of dial gears. This feature allows inspectors to have a more comprehensive view of all parts of the gear, ensuring a comprehensive inspection.

Multiple Light Source Matching: According to the characteristics and inspection needs of dial gears, POMEAS AFM can provide multiple light source matching modes (e.g. ring light, coaxial light, bottom light, etc.) to ensure clear imaging results under different lighting conditions.

Easy to operate: POMEAS AF microscopes are designed with a simple human-machine interface, which is easy to operate and understand. Inspectors can get started quickly, reducing training costs and time.

Data storage and analysis: Through the USB interface, POMEAS AFM can conveniently store pictures and dynamic videos for subsequent data analysis and report production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com