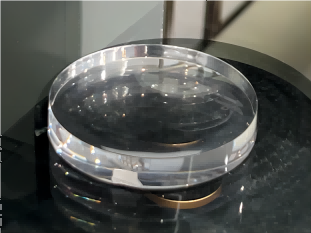

Spectral Confocal Sensor Measures Surface of Transparent Mirror Material

Program Background:

Transparent mirror materials, such as glass and transparent plastics, have extremely high demands on their surface quality during manufacturing and application. The surfaces of these materials may have tiny scratches, dents, uneven thicknesses, etc., which not only affect the aesthetics, but also may have a serious impact on the performance and service life of the product. Traditional measurement methods, such as contact measurement or optical projection measurement, often have limitations when measuring transparent mirror materials, such as the tendency to scratch the surface and the inability to accurately measure small variations. Therefore, it is important to find an efficient, accurate and non-contact measurement method. Spectral confocal sensors, as an advanced non-contact measurement technology, provide an effective solution to this problem.

Spectral Confocal Sensor Characteristics:

Superior to traditional measurements: The spectral confocal sensor realizes non-contact measurement of the surface topography of objects by means of the spectral confocal principle. Compared with traditional measurement methods, it avoids scratches and abrasions that may be caused by contact measurement, and overcomes the limitations of optical projection measurement on transparent materials.

With stability and high measurement accuracy: The spectral confocal sensor utilizes advanced optical and electronic technologies to maintain stable measurement performance in a variety of environments. Its high-precision measurement capability makes it capable of capturing minute changes in the surface of transparent mirror materials, such as tiny scratches, bumps, etc., providing a reliable basis for product quality control.

Suitable for accurate measurement of various materials: The spectral confocal sensor is not only suitable for the measurement of transparent mirror materials, but also widely used in the measurement of metals, plastics, ceramics and other materials. Its wide applicability makes it a multi-functional measurement tool that can meet the measurement needs of different industries.

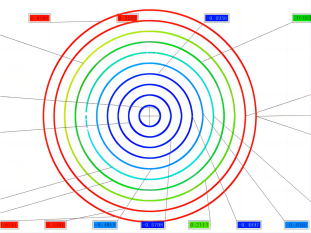

When measuring the surface of a transparent specular material, the spectral confocal sensor emits a beam of light of a specific wavelength which is reflected and refracted when it comes into contact with the surface of the object to be measured. The sensor receives and analyzes the reflected and refracted light and calculates the topography of the surface. Conventional optical measurement methods often have difficulty in accurately capturing the surface topography of transparent mirror materials due to their special light transmission properties. Spectral confocal sensors, however, are able to penetrate to a certain depth on the surface of transparent materials and accurately measure small changes in the surface by means of their unique operating principle.

In practical applications, the spectral confocal sensor can be adapted to the measurement needs of different transparent mirror materials by adjusting the measurement parameters (e.g., light source wavelength, measurement angle, etc.). At the same time, its high-precision measurement capability makes it possible to capture minute defects and variations on the surface, providing strong support for product quality control. In addition, the spectral confocal sensor has the advantages of fast measurement and easy integration, which can greatly improve the production efficiency and automation level.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com