How to choose the right laser autofocus microscope for your application scenario?

Laser autofocus microscopes are now available in a wide variety on the market, but how do you choose the right laser autofocus microscope? This article today takes you through the selection process.

The requirements for laser autofocus microscopes vary from application to application, such as semiconductor manufacturing, 3C electronics, and materials science.

In semiconductor manufacturing, accuracy and stability are critical. Due to the extremely small size of semiconductor chips and the complexity of the manufacturing process, laser autofocus microscopes are required to provide high-resolution images and precise focusing capabilities to ensure accuracy and reliability during the chip manufacturing process. In addition, semiconductor manufacturing is often conducted in dust-free environments, so the selected system should have good dustproof performance and be able to adapt to the harsh production environment.

For the 3C electronics industry, speed and flexibility can be key factors. As 3C electronics products are replaced at a faster rate, efficient inspection equipment is needed on the production line. A laser autofocus microscope should be able to focus quickly, adapt to the inspection of different sizes and shapes of electronic parts, and be easily integrated with automated production lines to improve productivity.

Versatility and scalability are important considerations in materials science research. Materials scientists may need to observe and analyze a variety of different types of materials, including metals, ceramics, polymers, and more. Therefore, laser autofocus microscopy systems should be broadly applicable and able to adapt to the properties of different materials. At the same time, it is desirable for the system to be scalable so that new modules or accessories, such as spectral analysis modules, can be added according to research needs.

In addition to the specific needs of the application scenario, the following aspects should be considered to select a laser autofocus microscope system:

I. Focusing performance. This includes static and dynamic focusing capabilities, focusing speed and accuracy. An excellent laser autofocus microscope system should be able to quickly and accurately focus on different types of surfaces, both static and dynamic moving.

II. Image quality. A high-resolution image provides more detailed information, which helps in accurate analysis and detection. At the same time, the contrast and color reproduction of the image should be good.

III, easy to integrate and operate. The system should be easy to integrate with existing equipment and software, and easy and convenient operation, reducing training costs and difficulty in use.

IV, reliability and stability. In the industrial production environment, the system needs to run stably for a long time, so reliability is the key. Choose brands and products with good reputation and after-sales service can ensure stable operation and timely maintenance of the system.

V. Price and cost-effective. According to their own budget, comprehensively consider the performance and price of the system, and choose a cost-effective laser autofocus microscope system.

Choosing the right laser autofocus microscope system for your application scenario requires comprehensive consideration of a number of factors, including the specific needs of the application scenario, focusing performance, image quality, ease of integration and operation, reliability and stability, and price. By carefully evaluating and comparing different products, you can choose the laser autofocus microscope that best suits your needs, bringing greater convenience and benefits to your work and research.

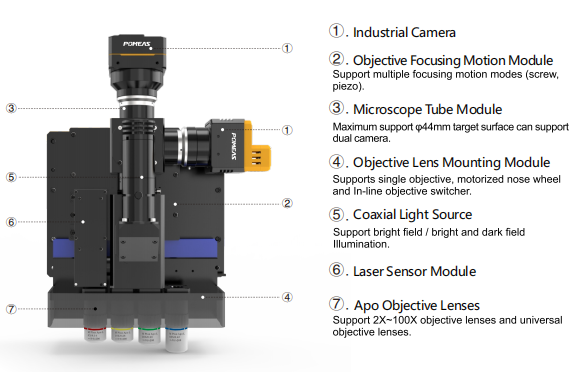

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com