Accurate measurement of the diameter of needles, a critical component in medical, pharmaceutical and precision manufacturing applications, is essential. However, the small diameter and elongated shape of needles, which are often measured with high precision, make the measurement process challenging.

Measurement challenges:

1. The tiny size of the needles requires high resolution and accuracy of the measurement equipment;

2, the elongated shape of the needle may cause the measurement to be easily disturbed by external factors, such as light refraction, vibration and so on;

3, the position of the needle in mass production may have a small offset, which also puts high demands on the stability and repeatability of the measurement.

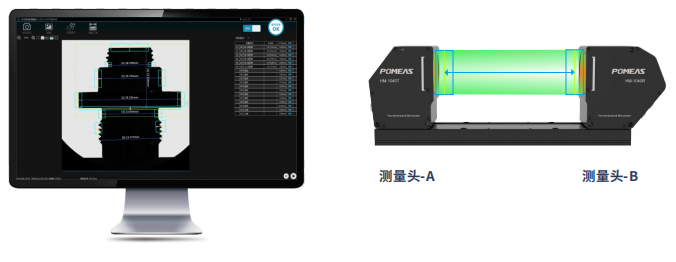

Working Principle of Line Laser Measuring Instrument:

The line laser measuring instrument realizes the precise measurement of the product dimensions by means of two line laser sensors directed against each other. This measurement system utilizes the highly directional and monochromatic nature of the laser beams to form a bright laser line on the surface of the object to be measured. When two sensors are placed opposite each other and emit laser light simultaneously, they capture information about the position of the light spots on each side of the object. By calculating the distance between these two light spots and combining it with the known angle of the laser beam and the object distance, the dimensions of the object to be measured can be accurately calculated.

Advantages of measuring needle diameters with line laser measuring instruments:

1. High stability and immunity to interference: Even if there is a positional offset of the workpiece, the line laser gauge ensures the accuracy of the measurement results through its precise optical system and algorithmic adjustments. Its unique alignment measurement method effectively reduces the interference of light refraction, vibration and other external factors.

2. High accuracy over the entire field of view area: The Line Laser Gauge maintains highly accurate measurement performance over the entire field of view area. This means that no matter where the needle is located in the measurement field of view, consistent measurement accuracy can be obtained, thus meeting the demand for high-precision measurement of needle diameter.

3. Flexible and easy-to-use setup tools: The line laser gauge is equipped with a wealth of setup tools that allow the user to easily adjust the measurement parameters and calibration process according to the actual measurement needs. This not only increases the flexibility of the measurement, but also simplifies the operation process, so that non-professionals can quickly get started and make accurate measurements.

4. Extremely high measurement accuracy: The measurement accuracy of the line laser gauge can reach ±0.01um level, which is crucial for the measurement of such tiny dimensions as needles. Such high accuracy ensures the reliability and consistency of the measurement results, providing strong support for quality control during the production process.

With its high stability, anti-interference, high accuracy over the entire field of view, flexible and easy-to-use setup tools, and extremely high measurement accuracy, the POMEAS line laser gauge shows great potential and value in the field of needle diameter measurement.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com