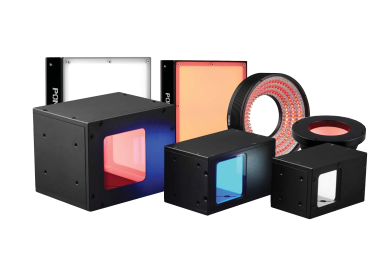

When detecting surface imperfections on objects in industrial application scenarios, choosing the right light source is critical. The choice of light source directly affects the quality of the image and the accuracy of the detection. Below are several types of light sources that are suitable for detecting surface defects in industrial applications:

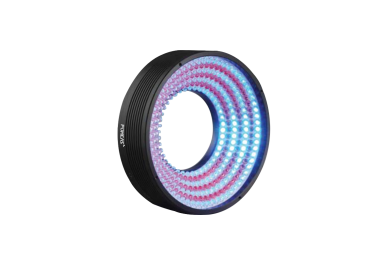

1. Ring light source

- Features: The ring light source is made of LEDs arrayed by structural optimization design, providing different lighting angles and color combinations, which can avoid the shadow phenomenon and highlight the imaging features. At the same time, it can be equipped with diffusers to guide the light, making the light more uniform and soft.

- Application areas: Ring light source is widely used in PCB substrate inspection, IC component inspection, microscope illumination, liquid crystal correction, plastic container inspection, integrated circuit printing inspection and other scenarios. These applications require fine inspection of the object surface to identify scratches, spots, holes and other defects.

2. Coaxial light source

- Features: Coaxial light source through a specific optical design, so that the light is perpendicular to the object being observed, greatly reducing the impact of light scattering and reflection. This type of illumination eliminates shadows caused by uneven surfaces and improves imaging clarity, making it ideal for detecting surface details.

- Application areas: Coaxial light source is most suitable for surface scratch detection, chip and wafer damage detection, marking point positioning and packaging barcode identification. It is especially suitable for metal, glass and other highly reflective objects surface inspection, can accurately reveal the small defects.

3. Bar light source

- Features: Bar light source is the preferred light source for large square structure, the color can be freely combined according to the demand, and the light angle can be flexibly changed. It is widely used in scenes that require uniform illumination over a large area.

- Applications: Strip light sources are commonly used for LCD character inspection, connector pin flatness inspection, liquid crystal component inspection, and large-area object surface scratch and crack inspection. All of these applications require the light source to provide stable and uniform illumination in order to accurately identify defects on the surface of the object.

4. Surface light source

- Characteristics: Surface light source is a kind of plane illumination light source, the LED is optimized by the structure of the uniform cloth at the bottom or around the light source, forming a uniform irradiation light. It is especially suitable for scenes where the contour and edge shape of objects need to be observed.

- Application areas: Surface light source is used for contour measurement, size measurement, glass bottle breakage and foreign object detection, transparent object surface scratches and internal foreign object detection and so on. In scenes where transparent objects are detected or where high contrast images are required, the surface light source provides effective illumination support.

5. Special light source (such as infrared light source, ultraviolet light source)

- Characteristics: infrared light source and ultraviolet light source have special physical characteristics, infrared light source penetrating ability, suitable for detecting objects with poor light transmission; ultraviolet light source is sensitive to the subtle features of the surface, suitable for detecting the contrast is not obvious enough.

- Application areas: infrared light source is commonly used in brown oral liquid impurity detection and other scenes that require penetrating lighting; UV light source is used for capacitive screen ITO circuit detection, UV glue overflow detection, anti-counterfeiting code content detection and other anti-counterfeiting needs of the detection project.

When selecting a light source for detecting surface defects in industrial applications, it is important to consider the material, shape, surface characteristics, and inspection requirements of the object to be inspected. Ring light sources, coaxial light sources, strip light sources and surface light sources are some of the common types of light sources, each of which has its own characteristics and is suitable for different inspection scenarios.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com