In modern industrial production, high-precision and high-efficiency measurement and inspection is the key link to ensure product quality and production efficiency. As a special lens designed for high-precision visual inspection, telecentric lens, with its four unique features - ultra-low distortion, high depth of field, high precision and large field of view - has shown its undeniable advantages and wide application prospects in the field of automated measurement.

1. Ultra-low aberrations

The design principle of the telecentric lens effectively reduces geometric aberrations in the imaging process, including radial and tangential aberrations, thus ensuring the accuracy and reliability of the measurement results. This feature is particularly important for the dimensional measurement of precision parts, because it can avoid measurement errors caused by lens aberrations, ensuring the authenticity and traceability of measurement data.

2. High depth of field

The high depth of field of the telecentric lens makes it possible to obtain a clear and consistent imaging effect within the same working distance, whether it is a small undulation on the surface of the object or a feature point at different heights. This advantage is especially critical when detecting products with complex three-dimensional structures or uneven surfaces, such as electronic components, automotive parts, etc., greatly improving the flexibility and applicability of the measurement.

3. High precision

Combining high-precision imaging with precise mechanical structure design, telecentric lenses are able to realize micron or even nanometer precision measurement of target objects. This high precision not only meets the strict requirements of product quality control in industry, but also provides strong support for high-precision measurements in scientific research, medical and other fields. In automated production lines, telecentric lenses can ensure that every product meets the design specifications, reducing the defective product rate and improving overall production efficiency.

4. Large field of view

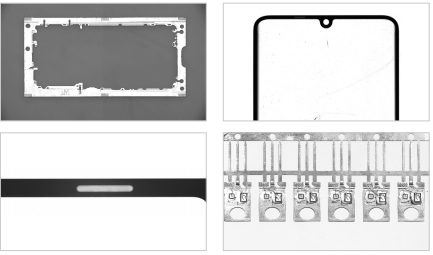

The large field of view feature enables the telecentric lens to capture a large range of image information at one time, reducing the number of scans and the need for image splicing, and improving inspection efficiency and ease of data processing. In scenes where large products or multiple products need to be inspected at the same time, such as panel inspection, circuit board inspection, etc., the large field of view of the telecentric lens can significantly increase the speed of inspection and reduce time costs.

Applications:

- Dimension Measurement: Telecentric lenses can be used to accurately measure the external dimensions of all kinds of products, such as length, width, height, diameter, etc., which are widely used in machining, electronic components, aerospace and other fields.

- Defect detection: With its high resolution and high precision, telecentric lenses can detect minor scratches, cracks, stains and other defects on the surface of products, which is an indispensable inspection tool for semiconductors, LCD panels, medical devices and other industries.

- Automated production line: The automated inspection system integrating telecentric lenses can realize efficient and accurate online inspection, provide real-time feedback on product quality information, and help enterprises realize intelligent production and quality traceability.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com