Nine machine vision light source characteristics and applications

In machine vision systems, the choice of light source is crucial, which directly affects the quality of the image and the accuracy of subsequent image processing. Different light source types are suitable for different inspection scenes and target objects.

Parallel light sources:

Features: Provides uniform and parallel light irradiation, reduces shadows and reflections, especially for objects with flat surfaces that require high-precision measurements.

Applications: e.g. electronic component inspection, flatness measurement, etc.

Surface light source:

Characteristics: large light-emitting area, soft and uniform light, suitable for scenes that require uniform illumination over a large area.

Applications: such as surface quality inspection of paper, fabric and other materials.

Ring light source:

Characteristics: The light source is arranged in a ring around the lens or camera, providing uniform shadow-free illumination, especially suitable for the inspection of round or cylindrical objects.

Applications: such as defect detection of screws, bearings and other mechanical parts.

Strip light source:

Characteristics: long bar-shaped luminous body, suitable for scenes that require linear lighting, such as scanning, positioning, etc..

Applications: such as barcode recognition, 1D code scanning, etc.

Point light source:

Characteristics: small range, high brightness, commonly used in local focus lighting, highlighting specific features of the object.

Applications: such as marking point positioning, tiny parts detection, etc.

Coaxial light source:

Characteristics: light source and camera lens coaxial, through a special optical design to reduce shadows and reflections, especially for strong reflection or surface uneven objects.

Applications: such as metal surface scratch detection, glass products defect detection, etc.

Dome light source:

Characteristics: The top of the light source is hemispherical or conical, providing uniform and soft illumination, reducing shadows and reflections.

Applications: e.g. inspection of spherical or curved objects, such as fruits, cosmetic bottles, etc.

Infrared light source:

Characteristics: emits infrared light, which is not visible to the human eye but can be captured by an infrared camera, suitable for scenarios where visible light interference needs to be avoided.

Applications: such as night vision, thermal imaging, etc. In machine vision, it is often used to detect defects inside opaque or semi-transparent materials.

UV light source:

Characteristics: emits ultraviolet light, which has an excitation effect on certain substances (e.g. fluorescent substances), causing them to emit visible light.

Applications: e.g. detection of fluorescent markers, UV curing monitoring. In machine vision, it can be used to detect substances with fluorescent properties or for non-destructive testing of specific materials.

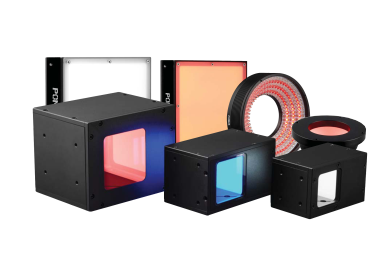

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com