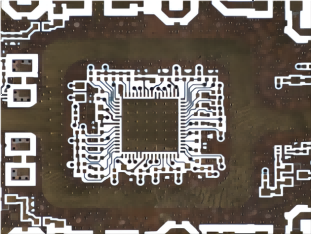

In the electronics manufacturing industry, printed circuit boards (PCBs) serve as the support and connection carriers for electronic components, and their dimensional accuracy is directly related to the overall performance and reliability of the product. Therefore, the dimensional inspection of PCB is an indispensable part of the production process. FA lenses (fixed focal length lenses) play a vital role in PCB dimensional inspection by virtue of their high precision, high resolution and stability.

High-precision imaging ensures accurate dimensional measurement

With its excellent imaging quality and high-precision features, the FA lens is able to clearly capture minute details and edge contours on PCBs. During dimensional inspection, this fine image information provides a reliable basis for subsequent measurement and analysis. By accurately measuring the dimensions of each part on the PCB, the FA lens ensures the accuracy and reliability of the inspection results, providing a strong guarantee for product quality control.

Large depth of field design, adapting to complex inspection needs

PCB size inspection often involves multiple layers and complex structures, such as multilayer boards, through-holes, pads, etc. FA lenses are usually designed with a large depth of field, which is able to clearly present the different layers and details of the PCB at the same time, avoiding the blurring or distortion caused by the lack of depth of field. This design makes the FA lens more flexible and versatile in the inspection process, and can easily cope with a variety of complex inspection needs.

High-speed inspection, improve productivity

In the electronics manufacturing industry, production efficiency is one of the key factors in the competitiveness of enterprises, FA lens combined with advanced machine vision system, can realize high-speed inspection of PCB size. Through optimized algorithms and high-speed data transmission technology, FA lenses can complete a large number of PCB size measurement work in a very short time, significantly improving production efficiency. This not only helps to shorten the time-to-market, but also reduces production costs and improves the market competitiveness of enterprises.

Automation Integration to Reduce Human Error

Traditional PCB size inspection often relies on manual operation, which is characterized by human error and low efficiency. FA lenses, as an important part of the machine vision system, can be easily integrated with automated production lines. By automating the inspection process, FA lenses can reduce human intervention, lower the probability of human error, and improve the stability and consistency of inspection results. At the same time, automated inspection also reduces labor intensity, improves the working environment, and enhances employee job satisfaction and efficiency.

Intelligent analysis to optimize the inspection process

FA lens in PCB size inspection not only provides high-precision image information, but also combines intelligent analysis algorithms to dig deeper into the inspection results. Through the intelligent analysis of the inspection data, companies can timely identify problems in the production process and take appropriate improvement measures. In addition, intelligent analysis can help optimize the inspection process, improve inspection efficiency and accuracy, and provide strong support for the continuous improvement and innovation of enterprises.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com