Precise application of zoom lenses for dimensional inspection of hardware parts

In the hardware manufacturing industry, the accuracy of dimensional inspection is directly related to product quality and safety. With the progress of science and technology, the zoom lens, as an advanced visual inspection tool, is gradually becoming an indispensable part of the hardware size inspection field. Its unique ability to quickly adjust the focal length brings unprecedented convenience and efficiency to the inspection work.

Efficient switching with full coverage

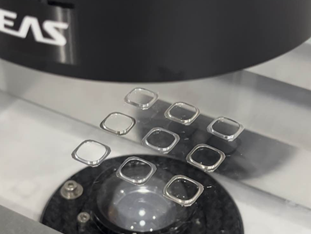

The most significant feature of the zoom lens is its ability to seamlessly switch from wide-angle observation to macro zoom in a short period of time. This feature allows inspectors to easily cover a full range of hardware inspections from the overall structure to local details without having to frequently change lenses or adjust the position of the equipment. Whether it is macro size measurement of large hardware or micro surface defect detection of small precision parts, the zoom lens can handle it with ease and ensure the comprehensiveness and accuracy of the inspection results.

Capture Details, Present Precisely

Hardware in the production process, often due to material, process and other factors lead to surface scratches, cracks, corrosion and other defects, these details often have an important impact on the performance and service life of the product. The zoom lens, with its high magnification ability, can penetrate into the minutiae and clearly present the details of the surface texture and defect patterns of the hardware on the inspection screen. This not only helps inspectors to quickly and accurately identify the problem, but also provides a strong basis for subsequent quality control and process improvement.

Improve efficiency and reduce costs

Traditional hardware size inspection methods often rely on manual measurement or fixed focal length lenses, which is not only time-consuming and laborious, but also susceptible to errors caused by human factors. The application of zoom lens greatly improves the inspection efficiency and reduces human intervention, thus lowering the inspection cost. At the same time, its high precision and high stability performance also ensures the reliability and consistency of the inspection results, which brings significant economic benefits to hardware manufacturing enterprises.

Intelligent trend, the future is promising

With the continuous development of intelligent manufacturing and machine vision technology, the application of zoom lens in hardware size inspection will be more extensive and in-depth. In the future, through the deep integration with AI algorithms, big data and other technologies, the zoom lens is expected to realize a more intelligent inspection process, such as automatic identification of defect types, prediction of potential problems, optimization of the inspection path and so on. This will further enhance the intelligent level of hardware inspection and push the whole industry in the direction of more efficient, more accurate and more intelligent.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com