In the metal processing and manufacturing industry, every detail is crucial, from tiny scratches to precise dimensional measurements, all directly related to the quality and performance of the product. Industrial FA lenses (fixed focal length lenses), as a key component in machine vision systems, are gradually becoming an indispensable tool in metal parts inspection and quality control.

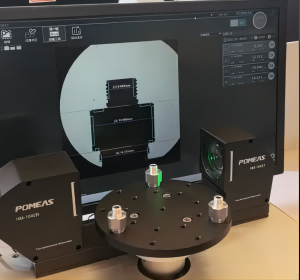

First, high-precision dimensional measurement

FA lenses play an important role in dimensional measurement of metal parts due to their high imaging quality and strong resolution. Whether it is complex geometry or small size changes, FA lenses can accurately capture and ensure the accuracy and reliability of the measurement results. This high-precision measurement capability is crucial for quality control during metal parts processing, and can effectively avoid the generation of scrap due to dimensional deviations.

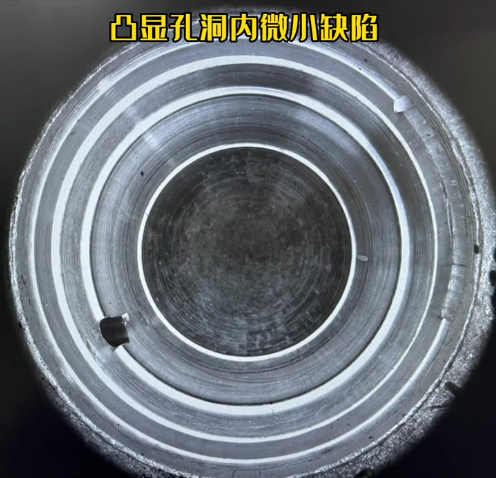

Second, surface defect detection

Surface defects such as scratches and pits inevitably occur on metal parts during the production process. These defects not only affect the aesthetics of the product, but also pose a potential threat to its performance. Industrial FA lens through high-resolution imaging, can clearly show every detail of the surface of the metal parts, so that inspectors can easily identify and eliminate these defects. This efficient way of detecting surface defects greatly improves productivity and product quality.

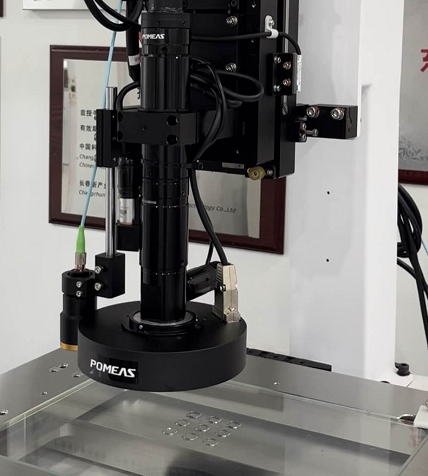

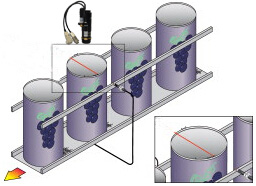

Third, automated production line integration

With the development of industrial automation, more and more metal parts production lines begin to use machine vision systems for automated inspection. As an important part of the machine vision system, industrial FA lens can be seamlessly integrated into the production line to realize online real-time inspection of metal parts. This type of automated inspection not only reduces manual intervention and improves inspection efficiency, but also greatly reduces detection errors caused by human factors.

Fourth, flexible response to diversified needs

Metal parts are of various types and shapes, and have different requirements for inspection equipment and lenses. Industrial FA lens by adjusting the focal length and aperture and other parameters, can flexibly cope with different metal parts inspection needs. Whether it is a large-sized steel plate or a small precision parts, FA lenses can provide clear, accurate imaging to ensure the reliability of the test results.

Compared to other types of lenses, industrial FA lenses have a significant cost advantage. Its manufacturing cost is low, and the service life is long, and the maintenance cost is relatively low. In the field of metal parts inspection, the wide application of FA lenses not only improves productivity and product quality, but also brings significant economic benefits for enterprises.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com