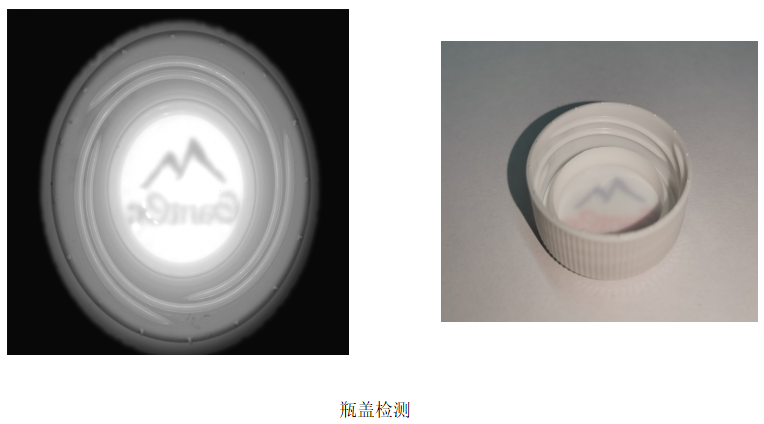

Bottle cap testing requirements:

① Detection content: comprehensive detection of beverage bottle cap density circle damage, burrs, deformation, color and other defects.

② Detection speed: the system needs to achieve a high speed of 1000 bottle caps per minute.

③ Defect control: able to accurately identify and report defects within a minimum of 0.3 mm.

Vision Solution

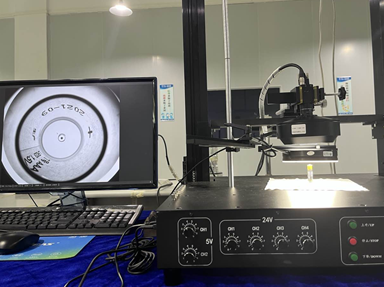

Optical Lens: POMEAS five megapixel industrial lens is used to ensure high resolution image capture, which can clearly present the tiny defects on the bottle caps.

Industrial Camera: POMEAS Gigabit Ethernet industrial camera is used to support high-speed data transmission and image capture. The fast response and stability of Gigabit Ethernet camera can ensure that each cap can be accurately photographed and recorded under the speed of 1,000 caps per minute.

Machine vision light source: Choosing a bar light source can provide uniform and stable light, which helps to highlight defects on the surface of the bottle cap, such as burrs and deformation, and at the same time reduces the impact of shadows and reflections on the image quality.

Program Advantages:

1、High-resolution image acquisition and high-speed data transmission to ensure the accuracy and real-time detection results.

2、Optimized light source design and image processing algorithms to improve the sensitivity and accuracy of defect detection.

3、Automated inspection process reduces manual intervention, reduces labor intensity and cost, and improves production efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION