Innovative applications and advantages of zoom lenses in laser welding

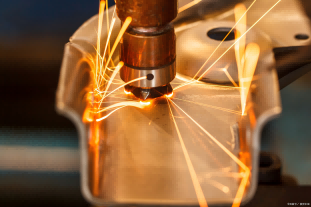

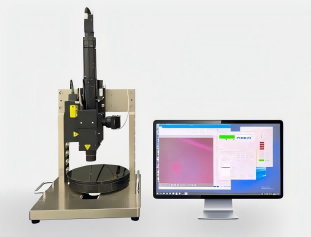

With the increasing requirements of modern industry for precision and efficiency, laser welding technology, as a high-precision and high-speed processing means, has been widely used in aerospace, automobile manufacturing, electronic devices and other fields. As a precision optical component, POMEAS has developed a point laser focusing solution for zoom lenses, whose unique features play an irreplaceable role in the laser welding process, greatly enhancing the precision and efficiency of welding.

The core advantages of the zoom lens point laser focusing solution:

Flexible zoom, high adaptability: The variable lens point laser focusing solution is able to flexibly adjust the focal length within a certain range according to the needs of different welding tasks, thus realizing precise focusing on different distances and sizes of weld seams. This high degree of adaptability ensures that the laser beam is always in the best focus state during the welding process, avoiding welding defects caused by improper focus.

High-definition imaging with low distortion: Combined with advanced optical features such as high definition, large depth of field and low distortion, the zoom lens provides stable and clear image output, enabling operators to accurately judge the welding position and status, and adjust welding parameters in time to ensure welding quality.

Enhance welding precision and efficiency: In laser welding, precise focus control is the key to ensure welding quality. The zoom lens point laser focusing solution can adjust the focus in real time to ensure that the laser beam is always accurately focused on the weld, no matter how the position of the weld changes, it can realize high-quality welding, and at the same time, it reduces the time wasted due to the repeated adjustment of the focus, and improves the welding efficiency.

Enhanced automation level: With the development of industrial automation, laser welding systems are moving towards a higher degree of automation. The zoom lens, as an important part of the intelligent welding system, can be tightly integrated with other sensors and control systems to realize automated monitoring and adjustment of the welding process, further improving productivity and stability.

Laser welding is widely used to join structural body parts in complex automobile manufacturing processes. Due to the complexity and diversity of the body structure, the position, length and depth of the weld seams are different, the traditional fixed focal length lens is difficult to meet all the welding needs. After adopting the zoom lens, the system can automatically adjust the focal length according to the characteristics of different weld seams, ensuring that each weld seam can be accurately and efficiently welded, which greatly improves the manufacturing quality and production efficiency of the whole vehicle.

The application of variable lens point laser focusing solution in laser welding not only improves the welding precision and efficiency, but also enhances the adaptability of the system and the level of automation, which is an important force to promote the development of laser welding technology.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com