Solutions for measuring springs with in-line image measuring instruments

As a part with elasticity and variable shape, springs have many difficulties in the measurement process:

1. The shape and size of a spring may change due to small differences in the manufacturing process, which makes it difficult to accurately capture its dimensions with traditional measurement methods.

2. Springs are prone to deformation due to external forces during measurement, which further increases the difficulty of measurement.

3. It is also a challenge to efficiently and accurately complete the measurement of a large number of springs during the mass production of springs.

The need for spring measurement:

Accurate measurement data is critical in the production and quality control of springs. Manufacturers need to ensure that each spring is dimensionally correct for its design to ensure performance and longevity in service. At the same time, the measurement process needs to be as fast and automated as possible in order to increase productivity and reduce costs. As a result, finding a way to efficiently and accurately measure spring dimensions has become a pressing need in the spring manufacturing industry.

Solution:

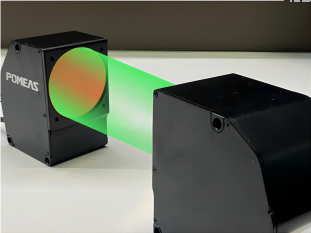

POMEAS In-Line Image Gauge can be embedded in the production line to measure the dimensions of the products. 1000 springs can be measured in a minute, ignoring the deviation of the spring position, and the dimensions of the springs can be measured quickly and with a high measuring accuracy of 0.1um, which can satisfy the manufacturer's high demands on the quality of the products.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION