Double telecentric lens principle, characteristics and applications

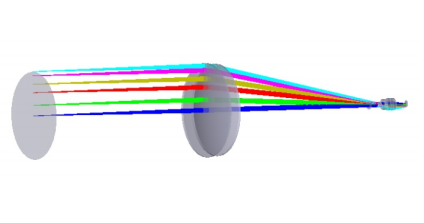

Double telecentric lens principle:

The Double Telecentric Lens achieves a high degree of precision and stability in imaging objects through its unique optical design. The core lies in a diaphragm (also known as an aperture diaphragm or field of view diaphragm) cleverly set up inside the lens, a design that allows light emitted from the surface of the object to be adjusted to be approximately parallel to the light as it passes through the lens, whether entering or leaving the lens. This design effectively eliminates the imaging errors caused by the non-parallelism of light in conventional lenses, and in particular solves the problem of depth of field on the object side (the side where the object is located) and the problem of magnification changes on the image side (the side where the imaging chip is located). In short, the double telecentric lens realizes the constancy of the object-image relationship and the consistency of the measurement accuracy by ensuring the parallelism of the light rays.

Double telecentric lens features:

Ultra-low aberration and high depth of field: due to the strict control of light parallelism, the double telecentric lens is able to significantly reduce image aberration, making the imaging more realistic and accurate. At the same time, the high depth of field design allows the lens to maintain a clear image over a large working distance, even if the object is in a different position within the depth of field range, to ensure the stability and consistency of the measurement results.

Matching with external coaxial light source: Bilateral telecentric lenses offered by brands such as POMEAS can often be used with a specially designed coaxial light source. This light source design can further enhance the contrast and clarity of the image, especially suitable for high-precision measurement of the surface dimensions of large-sized objects, improving the reliability and efficiency of the measurement.

High precision and large field of view: The double telecentric lens combines the advantages of high precision and large field of view, enabling it to meet the needs of a variety of complex measurement scenarios. Whether it is a tiny part that requires high-precision positioning or a large workpiece that requires a wide scanning area, the dual telecentric lenses can provide stable image quality and accurate measurement results.

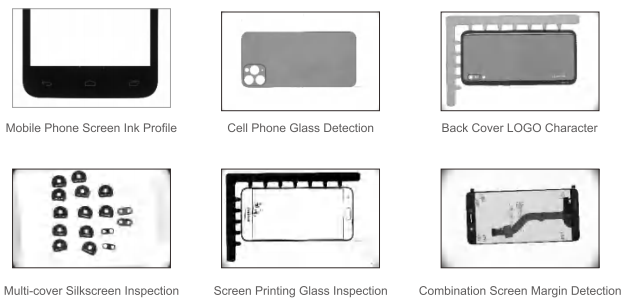

Double telecentric lens application:

Smartphone touch screen inspection: In the manufacturing process of smartphones, the double telecentric lens can be used to inspect the flatness, dimensional accuracy and defects of the touch screen to ensure product quality.

Liquid crystal panel inspection: The production of liquid crystal panels requires high dimensional and shape accuracy, and the double telecentric lenses can accurately measure the parameters of the panels to meet the demand for high-precision inspection.

Industrial Parts Measurement: Precision mechanical parts, such as air compressor parts, have a direct impact on the performance and life of the product in terms of size and shape accuracy. Double telecentric lenses play an important role in the measurement of these parts.

PCB Board Inspection: In the electronics manufacturing industry, PCB board inspection is a key part of ensuring correct circuit connections and stable performance. Double telecentric lenses can clearly image the tiny components and circuits on PCB boards, improving inspection efficiency and accuracy.

Double telecentric lens accessory options:

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com