In the field of precision measurement, flash meter as a kind of efficient, high-precision measurement equipment, its supporting measurement software plays a crucial role. An excellent flash meter measurement software can not only enhance the convenience of measurement, but also greatly expand the scope of application and measurement capability of the device.

The following are several notable features of the flash tester measurement software:

Multi-sensor composite measurement capability: The software supports composite measurement of image, spectral, laser and other sensors, which means that users can flexibly select or combine different sensors according to the measurement needs, thus realizing comprehensive and accurate measurement of complex workpieces. This multimodal measurement technology not only improves the flexibility and adaptability of measurement, but also further enhances the accuracy and reliability of the measurement results.

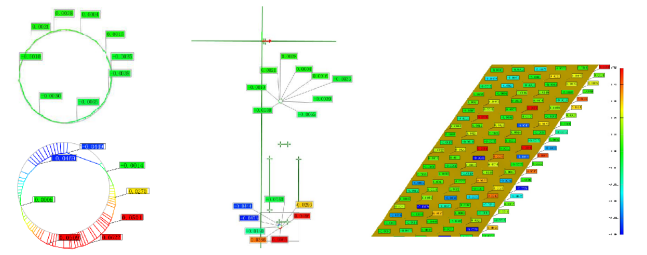

Complete dimensional and form tolerance calculation: The software has built-in perfect dimensional and form tolerance calculation function, which can automatically calculate and output all dimensional data and form tolerance information of the measured workpiece. This greatly simplifies data processing after measurement, improves work efficiency, and ensures the accuracy and traceability of measurement results.

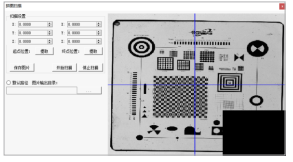

Dual or Multi-station Parallel Measurement: With a dual or multi-station solution, the software is able to support parallel measurement at multiple stations, which significantly improves measurement efficiency. By placing the part to be measured in multiple stations at the same time, the software automatically switches and controls the measurement tasks in each station, allowing for seamless and efficient operation. This parallel measurement mode is particularly suitable for high-volume, high-efficiency production environments.

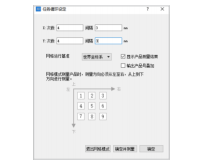

Grid Measurement and Fast Programming: For the measurement needs of multiple identical or similar products, the software provides a grid measurement function. With the preset grid layout and parameter settings, the software can quickly program and measure multiple products. This not only simplifies the measurement process, but also greatly improves the consistency and repeatability of measurements.

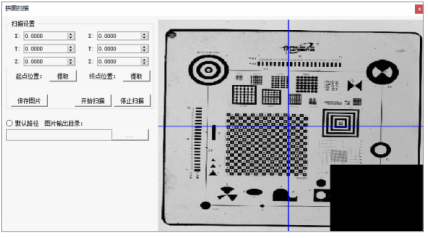

Image Stitching: The software supports image stitching, which allows multiple partial images to be stitched together into a complete global image. This is especially important when measuring large parts or parts that are out of the field of view of a single sensor. With image stitching, users can obtain more comprehensive and accurate measurement results.

Multiple point cloud 3D interaction modes: The software provides multiple point cloud 3D interaction modes, such as rotation, zoom, translation, etc., so that users can observe and analyze the measurement results more conveniently. Meanwhile, it also supports point cloud data editing and processing functions, such as denoising, smoothing, etc., to meet the different needs of users for measurement results.

Rich image pre-processing tools: In order to obtain clearer and more accurate measurement images, the software has built-in a variety of image pre-processing tools. These tools can denoise, enhance contrast, sharpen edges and other processing of the original image, thus improving the quality of the image and the accuracy of the measurement results.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com