What is an industrial CCD camera?

Industrial CCD camera, full name Charge-Coupled Device (CCD) industrial camera, is a camera device specially designed for industrial and commercial applications. Its core component is the CCD image sensor, the sensor through the photoelectric effect will be converted into electrical signals, and then generate digital images.

Industrial CCD camera definition and principle:

An industrial CCD camera is a camera that uses a charge-coupled device (CCD) as an image sensor. Its working principle is mainly divided into two processes: image sensing and image acquisition. In the image sensing process, the photosensitive element on the CCD sensor converts the received photon energy into electrons, which are accumulated within the pixel unit. Subsequently, in the image acquisition process, the CCD sensor outputs these charge values row by row and column by column, and converts them into digital signals through an analog-to-digital converter, which is ultimately further processed by the image processor and outputs clear image data.

Industrial CCD camera features and benefits:

1, High resolution: industrial CCD cameras usually have a high resolution, able to capture more fine image details, applicable to the need for high-precision measurement of the scene.

2, High sensitivity: CCD sensors respond well to light, even in a low-light environment can also capture clear images, suitable for poor lighting conditions in the industrial environment.

3, Low noise: due to the special structure and working principle of the CCD sensor, its output image noise is low, which helps to improve image quality.

4, Wide dynamic range: able to capture the details of the high light and low light areas at the same time, suitable for high-contrast scenes.

5, Strong anti-interference ability: strong resistance to electromagnetic interference, vibration and other environmental factors, to ensure stable work in harsh industrial environments.

Industrial CCD camera application scenarios:

Industrial production: tasks such as quality inspection, object recognition and precision measurement on automated production lines. For example, detecting dimensions and surface defects of parts in automobile manufacturing; detecting soldering quality of electronic components in electronics manufacturing.

Machine vision: As a key component of the machine vision system, it is used to guide robots to perform precise operations, such as part pickup, assembly and welding.

Scientific research: Capturing high precision images in astronomical observation, medical research and biological research, such as photographing the starry sky, cell structure and the growth process of plants and animals.

Surveillance and Security: Installation of surveillance cameras in areas such as public places, transportation systems and factories for safety monitoring and object tracking.

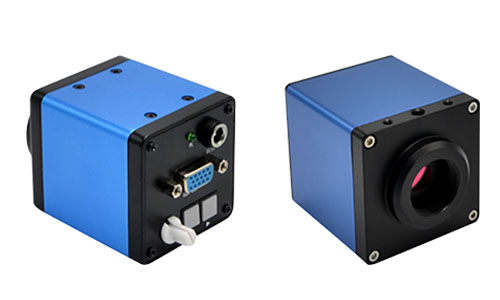

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com