Array measurement is an efficient, automated measurement method that is particularly suitable for scenarios where multiple identical or similar products need to be dimensionally measured. This method is widely used in high-precision measuring equipment such as image dimensioning machines.

Array measurement principle of operation:

Positioning the first product: First, multiple products to be measured are placed in a customized fixture (or jig) in a certain layout. This fixture ensures that the products maintain a stable position and attitude during the measurement process. By means of image recognition or mechanical positioning, the system precisely finds and locates the starting point of the first product to be measured.

Measuring the first product: Once the first product has been accurately positioned, the measuring instruments (e.g. laser rangefinders, high-precision cameras, etc.) start to measure the dimensions of the product. These measurements are recorded in real time and transferred to a computer for analysis and processing.

Automated moving platform: After the first product is measured, the system controls an automated moving platform (e.g., X-Y table) via computer to move the platform to the next product location. This moving process is often very precise to ensure that each product is accurately positioned and measured.

Continuous Measurement: With a click or a preset program, the system can automatically take dimensional measurements of each product in the fixture. Measurement data for each product is recorded individually and compared to preset standards or specifications to assess whether the product's quality meets requirements.

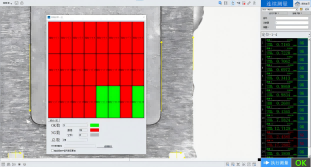

Arrayed measurements of detection effects:

Array Measurement Advantages:

- Efficiency: Array measurement is capable of handling multiple products at the same time, greatly improving measurement efficiency.

- Accuracy: Accuracy and reliability of measurement results are ensured by high-precision measuring instruments and automated control systems.

- Flexibility: Suitable for measuring products of various shapes, sizes and materials, just adjust the fixtures and measurement programs.

- Traceability: Measurement data for each product is recorded in detail, facilitating subsequent quality control and data analysis.

Arrayed measurement application areas:

Array measurement is widely used in many fields such as manufacturing, automotive industry, electronics industry, medical devices, etc., especially in scenarios where fast and accurate dimensional measurements of a large number of parts are required, such as precision machined parts, electronic components, and injection molded parts.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION