Measurement systems play a vital role in modern industrial production and scientific research. According to different classification criteria, measurement systems can be divided into different types.

Classification according to measurement differences

3D Measurement System: A 3D measurement system is capable of measuring an object in three dimensions and obtaining information such as the length, width, height, and the shape of each surface of the object. It usually adopts laser scanning, structured light and other technologies, and is characterized by high precision and high efficiency. In automotive manufacturing, aerospace and other fields, 3D measurement systems are widely used for parts inspection and assembly precision control.

2D measurement system: 2D measurement system mainly focuses on the measurement of flat dimensions of objects, such as length, width and diameter. It usually adopts methods such as optical imaging and contact measurement, and has the advantages of simple operation and lower cost. In the electronics manufacturing and printing industries, 2D measurement systems are commonly used for dimensional inspection of circuit boards and quality control of printed materials.

Classification according to differences in measurement methods

One-touch measurement (flash meter):One-button measuring instruments, also known as flash testers, are characterized by easy operation and fast measurement. Users only need to place the object to be measured in the measurement area, press the measurement button, the instrument can automatically complete the measurement process, and quickly give the measurement results. Flash testers are usually applied to occasions that require high measurement speed and relatively low measurement accuracy, such as the rapid inspection of production lines.

Imaging Instruments:Imager is a measuring instrument based on optical imaging technology. It takes an image of the object to be measured by means of a high-resolution camera, and then analyzes and measures the image using image processing software. With the advantages of high precision and non-contact measurement, the imaging instrument is suitable for the measurement of complex-shaped objects and the inspection of microscopic dimensions.

Measurement systems can be categorized according to measurement differences and measurement methods. In practical application, users should choose the appropriate measurement system according to the specific measurement requirements to improve the measurement efficiency and accuracy.

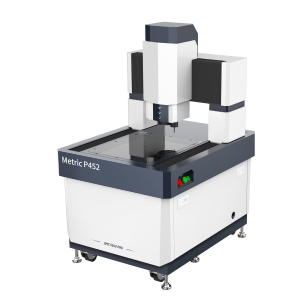

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION