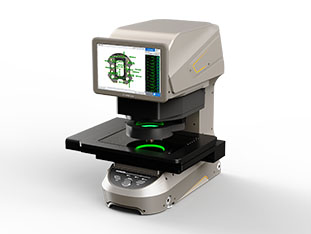

In this era of rapid technological development, with the high-speed forward movement of industry, high-precision image measuring instrument has gradually become a necessity in the factory. So what exactly is a high-precision image measuring instrument used for?

High-precision image measuring instruments enable fast and accurate dimensional measurements.

In industrial production, the dimensional accuracy of a product is critical. Whether it is a tiny electronic component or a large mechanical part, the dimensional deviation needs to be strictly controlled.

High-precision image measuring instrument can accurately measure the length, width, height, diameter and other dimensional parameters of the object in a short time through advanced image acquisition technology and precise measurement algorithms, providing reliable data support for product quality control.

The high-precision image measuring instrument can perform measurements of complex shapes.

For some workpieces with irregular shapes, traditional measuring tools are often difficult to measure accurately. The high-precision image measuring instrument is able to capture all-round images of objects with complex shapes, and then analyze them through software to accurately determine the contours and shape parameters of the objects. This is of great significance to industries such as mold manufacturing and automotive parts processing.

The high-precision image measuring instrument can also perform surface defect detection.

During the production process, scratches, cracks, pits and other defects may appear on the product surface. With the high-resolution image acquisition function of the image measuring instrument, subtle defects on the product surface can be clearly observed and quantitatively analyzed. This helps to detect problems in time and improve product quality and reliability.

High-precision image measuring instrument with efficient data processing and storage.

Measurement results can be quickly output in digital form and can be stored in a computer for subsequent data analysis and quality traceability. Meanwhile, the measurement software can also be integrated with the factory's production management system to achieve automated quality control and production process optimization.

High-precision image measuring instrument in industrial production can not only realize fast and accurate measurement, but also effectively detect complex shapes and surface defects, which provides powerful technical support for improving product quality, reducing production costs and enhancing enterprise competitiveness.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION