POMEAS 360° Interior Inspection Lens Features:

(1) Omni-directional inspection capability: The lens is capable of capturing the full view of the interior of the object under test without any dead angle, whether it is a cylinder, a pipe or any other complex shape of the internal structure, full coverage can be realized. This feature makes any defects or imperfections hidden in the interior of the inspection process have nothing to hide.

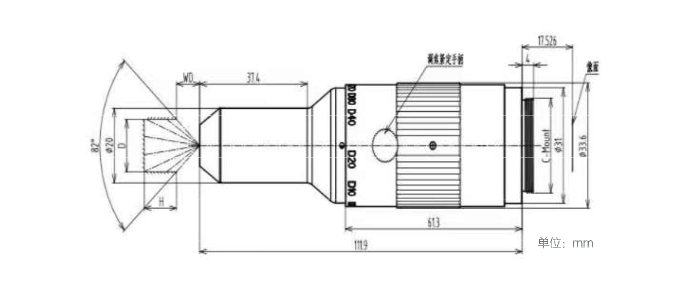

(2) High precision and adaptability: POMEAS 360° internal inspection lenses are designed and manufactured with a focus on precision and adaptability. The lens adopts special optical structure and material to effectively reduce image distortion and improve the accuracy of inspection results through refraction or special optical path design. At the same time, the lens can be adjusted and optimized according to different inspection needs to achieve the best detection results.

(3) High efficiency: Compared with the traditional single-point or linear scanning method, POMEAS 360° inner wall inspection lens can complete the comprehensive shooting of the inner wall at one time, which greatly improves the inspection efficiency. This high efficiency not only reduces the inspection time, but also reduces the labor cost, which is an important and indispensable tool in modern industrial production.

(4) easy to integrate and expand: The inspection lens is easy to integrate with high-definition industrial cameras, ring light source and other equipment to form a complete inspection system. At the same time, the system can be customized and optimized according to the actual needs to meet the inspection needs of different products.

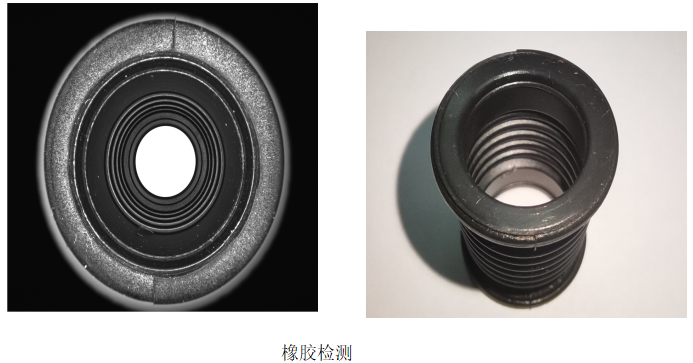

Measuring aperture difficulties:

① Complex aperture shapes: Many industrial products have complex aperture shapes, such as round, oval, polygonal, etc., and apertures of different sizes. This requires a high degree of flexibility and adaptability of the measurement equipment, able to cope with a variety of shapes of holes.

② The inner wall defects are difficult to find: the inner wall of the aperture may have scratches, dents, corrosion and other defects, these defects are often hidden in the interior, difficult to find through the naked eye or traditional inspection means. Therefore, it is necessary to measure and identify them with the help of high-precision inspection equipment.

③ High measurement accuracy requirements: in some high-precision requirements of the industrial field, such as semiconductor, aerospace, etc., the aperture measurement accuracy requirements are extremely high. Any small error may lead to product quality problems or safety hazards.

④ Complex measurement environment: The industrial production environment is complex and variable, such as lighting conditions, temperature, humidity and other factors may have an impact on the measurement results. Therefore, the measurement equipment needs to have stable performance and anti-interference ability to ensure the accuracy of the measurement results.

POMEAS 360° internal inspection lens measures the hole diameter:

1. Comprehensive Dead-End Inspection: POMEAS 360° internal inspection lenses are capable of capturing a full view of the inside of an aperture without any dead ends, ensuring that every corner is detected. This comprehensive inspection capability allows any hidden defects or flaws inside to be accurately identified during the measurement process.

2. High Accuracy Measurement: Through special optical structure and material design, POMEAS 360° internal wall inspection lens can effectively reduce image distortion and improve the accuracy of measurement results. Meanwhile, with the high-definition industrial camera and image processing software, it can realize accurate extraction and analysis of key information such as aperture size and shape.

3. High-efficiency inspection: The inspection lens can complete the comprehensive shooting of the inner wall of the aperture at one time, which greatly improves the inspection efficiency. This high efficiency not only reduces the inspection time, but also reduces the labor cost, which helps enterprises to improve production efficiency and product quality.

4. Adaptable: POMEAS 360° inner wall inspection lens can be adjusted and optimized according to different inspection needs, in order to adapt to different shapes, sizes and materials of aperture measurement. This flexibility makes the lens have a wide range of applications in industrial production.

POMEAS 360° internal inspection lenses show unique advantages in measuring apertures, enabling comprehensive, highly accurate and efficient inspection of the inside of apertures. The application of this technology will help to improve the quality and safety of industrial products and promote the intelligent and automated process of industrial production.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com