Defect Detection Challenges

Defects can occur in any product, from manufactured goods to food products. There are many different types of defects, but some of the most common include:

- Dimensional defects: These are defects that occur when a product does not meet the specified dimensions.

- Material defects: These are defects that occur when a product is made from substandard materials.

- Manufacturing defects: These are defects that occur during the manufacturing process. For example, a piece of metal may be scratched or dented.

- Design defects: These are defects that occur in the design of a product. For example, a product may not be safe to use or it may not meet the needs of the customer.

Defects can have a significant impact on a product's quality and performance. They can also lead to customer dissatisfaction and product recalls. As a result, it is important to identify and correct defects as early as possible in the manufacturing process.

Challenges of Manual Defect Detection

Manual defect detection is the traditional method of identifying defects. It involves inspecting products visually or using other manual methods. While manual defect detection can be effective, it is also time-consuming and labor-intensive. It can also be difficult to identify defects that are not visible to the naked eye.

Challenges of Automated Defect Detection

Automated defect detection is a newer method of identifying defects. It involves using machines to inspect products for defects. Automated defect detection can be more efficient and accurate than manual defect detection, but it can also be more expensive. It can also be difficult to train machines to identify defects that are not well-defined.

Defect Detection Solutions

- Machine learning: Machine learning algorithms can be trained to recognize defects that are not clearly defined or difficult to detect manually.

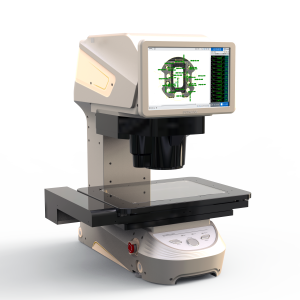

- Machine vision: Machine vision technology can be used to identify defects in products that are invisible to the naked eye.

- Image processing: Image processing: Image processing technology enhances the image of the product to make defects easier to recognize.

Defect detection is an important part of the manufacturing process. It helps to ensure that products are of high quality and that they meet the needs of customers. There are a number of different solutions available for defect detection, and the best solution for a particular application will depend on the type of defects that are being detected, the cost of the solution, and the accuracy of the solution.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com