As a mechanical transmission device, the screw is widely used in the field of industrial manufacturing and mechanical design. It has the function of converting rotary motion into linear motion and is commonly used in precision machine tools, industrial robots and other equipment.

The accuracy of dimensions is very critical in processes such as assembly and inspection of screws. Especially the accuracy of dimensions such as length, width and tooth spacing of the screw has a very important influence on the performance and service life of the screw. Therefore, strict dimensional control and inspection is a must.

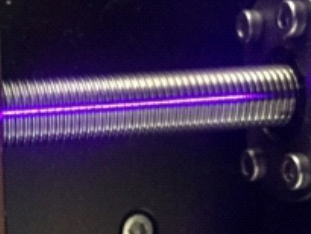

The POMEAS Laser Contour Sensor is a high-precision inspection device that enables high-speed and high-efficiency detection of the spacing between the teeth of a screw. It uses a laser beam from a laser light source to scan the surface of the screw, and measures the reflected light to obtain information on the shape and size of the surface of the screw, enabling efficient and high-precision detection of the spacing between the teeth of the screw.

Detecting effects:

Advantages of laser profile sensors:

1. The use of non-contact measurement methods enables highly accurate measurement results. The measurement accuracy is usually at the micron level, which is much higher than traditional measurement methods.

2. The measurement process can be completed very quickly, usually within a few milliseconds or tens of milliseconds. This is very useful for applications that require fast measurements to improve productivity and quality.

3. The laser profile sensor does not need to touch the measured object. It ensures that the measured object will not be damaged and avoids errors that may occur in traditional measurement methods.

4. It can measure in a wide measuring range and is suitable for measured objects of different sizes and shapes.

Laser profile sensors have the advantages of high accuracy, high speed, non-contact measurement, wide measuring range and automated measurement, etc. The use of POMEAS laser profile sensors to complete the detection of the spacing between the teeth of the screws can effectively improve the production efficiency and detection accuracy, to ensure the performance and quality of the screws, and then to improve the efficiency and stability of the entire mechanical device.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION