Image Gauge Applications|Precision Tool Parallelism and Other Dimensional Measurement Solutions

Precision tools have an important position in the machining industry, and their accuracy directly affects the machining quality and productivity. Therefore, the measurement of the dimensions of precision tools is particularly important.

Detection needs:

Simultaneously measure two-dimensional dimensions such as length and width of multiple precision tools as well as flatness and parallelism, and automatically determine whether the dimensions meet the requirements with an accuracy of 2μm.

Detection programme:

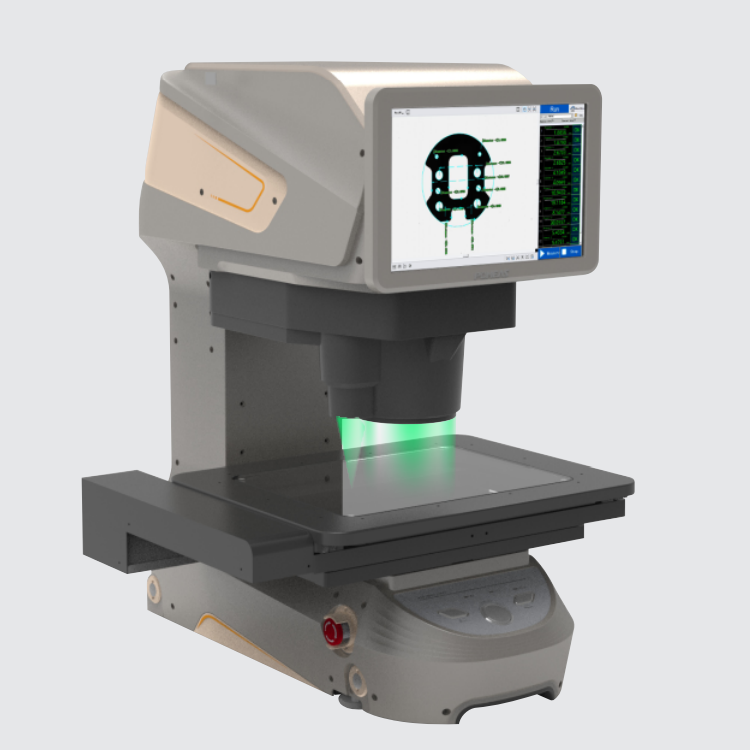

Image size measuring instrument is a kind of industrial camera, industrial lens, vision light source and image processing system, through the shooting image and its processing, so as to get the product image angle, edge and other information, and complete the size inspection of the high-precision measuring instruments, the use of POMEAS IMAGE3 max image size measuring instrument, high-precision mode, can be quickly and accurately complete the size inspection of precision tools.

Programme strengths:

1. High precision: The image measuring instrument is equipped with self-developed double telecentric industrial lenses, with low imaging distortion rate and true reproduction of the product image, which can achieve high-precision measurement and analysis.

2. Measurement speed: image measuring instrument can be placed at a time more than one tool workpiece, batch size inspection, effectively improve the detection efficiency.

3. Versatility: MAX image measuring instrument equipped with a spectral head, in addition to the completion of the plane size measurement, but also can measure the height/segment difference/flatness/thickness, etc., applicable to different areas of measurement needs.

4. Easy to operate: with easy-to-use operation interface and software, enabling users to easily carry out measurements and data analysis.

5. Intuitive data: Enter the tolerance size, automatically complete the size discrimination, qualified display "OK", unqualified display "NG" for users to understand and analyse.

6. Traceability: Measurement results can be output in a variety of formats to ensure the traceability and accuracy of measurement data.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0857

Fax:+ 86-0769-2266 0857

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

Software Copyright :2021SR0176001 抄袭必究, 技术支持:誉新源科技

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION