Motor gear is a common transmission method in mechanical transmission, its performance and service life are directly related to the stability and reliability of the whole mechanical system. As one of the most basic dimensional parameters in motor gear transmission, gear pitch has an important impact on the transmission efficiency, noise, vibration and other performance indicators of motor gears. Therefore, accurate measurement of motor gear tooth spacing has become a necessary condition to ensure the performance of motor gear transmission.

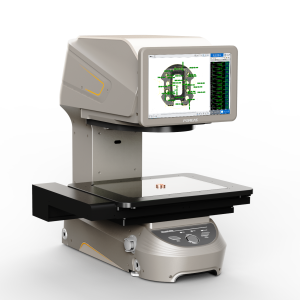

Measurement of motor gear tooth spacing can be measured using an image measuring instrument. Compared with the traditional manual measurement method, the image measuring instrument has the advantages of simplicity and speed, high precision, clear and intuitive data, high repeatability, etc., which can greatly improve the measurement efficiency and accuracy.

When carrying out motor gear tooth pitch measurement, suitable image measuring instrument and software should be selected, and careful preparation should be carried out before measurement to ensure the accuracy and reliability of the measurement results. In addition, the assessment and control of measurement errors should be carried out according to the specific conditions to ensure the validity and reliability of the measurement results.

The POMEAS IMAGE3 combines a wide range of measurement tools to solve the inherent problems of dimensional inspection and incorporates a one-button flash measurement principle for quick one-button measurement of motor gear spacing.

The procedure for motor gear pitch measurement using a POMEAS Image Gauge is as follows:

1. Place the gear to be measured on the image measuring instrument carrier, adjust the size of the measurement field of view and light source parameters according to the size of the workpiece.

2. The auto-focus function locates the workpiece, programs the dimensional items to be measured, and enters the tolerance data.

3. One button start, automatically start measuring, automatically judge the size parameters qualified or not, the data is clear and intuitive.

4. According to the measurement results of data analysis and statistics, the average value of gear tooth spacing, standard deviation and other parameters.

Using an image measuring instrument for motor gear tooth pitch measurement is a simple, fast, precise and reliable method that can greatly improve the measurement efficiency and accuracy, providing strong support for the stability and reliability of motor gear transmission.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION