Injection moulded products refers to the injection moulding products produced by injection moulding technology processing, including all kinds of packaging, parts, etc. Injection moulded products are widely used in our life nowadays and play a very important role. With the development of science and technology, the products are gradually developing in the direction of high precision and high quality, and injection moulded products need to go through a series of vision inspection in order to be used.

Pomeas is a machine vision and industrial automation core product supplier, for injection moulding parts quality inspection can provide a total solution to help manufacturing enterprises to improve product inspection efficiency and reduce costs.

1. Appearance Defect Identification

Solution:

①Pomeas has 4K zoom lenses, telecentric industrial lenses, FA lenses, line scanning lenses, etc., which can be selected according to the requirements.

②Pair with Pomeas Gigabit network industrial camera, vision light source and self-developed image processing system.

The vision inspection solution of Pomeas can complete the appearance identification clearly and quickly, and the products are diversified, and the configuration can be adjusted according to the actual products.

2. size data measurement

Solution:

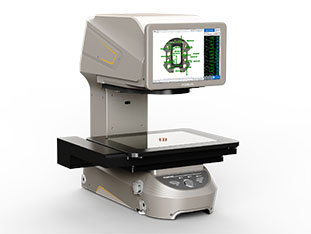

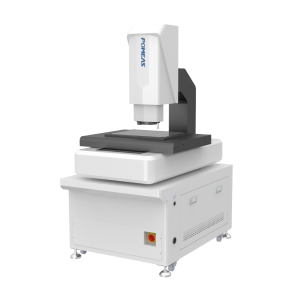

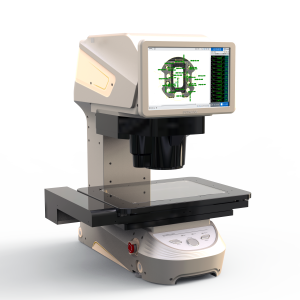

Using Pomeas IMAGE3 series MAX image measuring instrument, not only can measure the length, width, distance, diameter, arc and other plane dimensions of injection moulding products, but also for the height, flatness, segmentation and other 3D dimensional inspection needs are also applicable.

With fast measuring speed, high accuracy and repeatability, and easy-to-understand operation, Pomeas IMAGE3 MAX can be used for a wide range of dimensional measurements of injection moulded products.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com