Bearing parts are important components to support the movement of mechanical equipment, once there is a size deviation, it will lead to abnormal operation of the bearing, affecting the overall quality of the equipment, so it should be strictly tested. As industrial production requires higher and higher inspection efficiency and accuracy, what tools can be used to measure bearing dimensions to meet production needs?

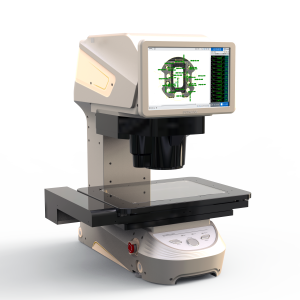

The use of Pomeas Image Dimension Measuring Instrument can simultaneously measure the bearing width, circle, hole diameter, hole distance, etc., and can solve the problems of low efficiency and poor consistency of traditional manual measurement.

Advantages of Image Measuring Instrument:

1. Pomeas image size measuring instrument has various models, not only the basic version with fixed measuring range φ100, but also the pro/plus version with wider measuring range, and the MAX version which can simultaneously measure the plane size and 3D dimensions such as height, segmentation, flatness, thickness, etc., to meet the inspection needs of different customers.

2. High measurement accuracy: equipped with self-developed double-sided double telecentric industrial lens, large depth of field, low distortion, high image reproduction, high measurement accuracy.

3. fast measurement speed: one second can measure nearly 100 parts, and can be batch measurement, greatly improving the detection speed.

4. automated, intelligent operation, the measurement process is simple and easy to understand, easy to start.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com