Softgel capsules are commonly used in medicines or health food, with portable, accurate dosage, easy to use and other characteristics. The quality of the softgel capsule will directly affect the efficacy of the drug, so it needs strict quality inspection to ensure that the appearance of no damage, bubbles, foreign objects and other defects.

For the defect detection of softgel capsules, many manufacturers are still using manual observation, which is not only inefficient, but also easy to fatigue, which may lead to misdetection or missed detection.

Pomeas is a machine vision and industrial automation product supplier, which can provide a complete set of machine vision inspection solutions for softgel capsule defect detection, achieving high efficiency and high accuracy.

Inspection solutions:

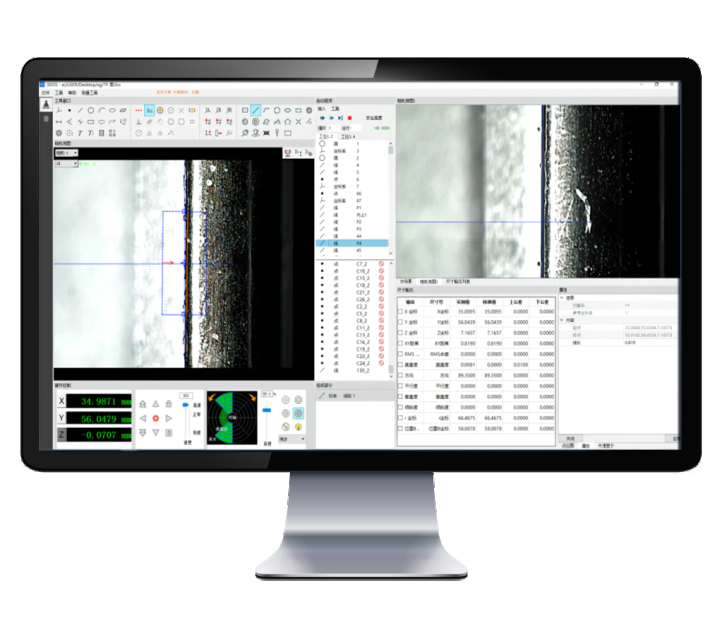

1. The lens is a five megapixel FA industrial lens from Pomeas, which can clearly obtain the image of the product in the field of view;

2. the camera uses Gigabit network industrial camera, stable transmission, high image quality;

3. with ring vision light source and self-developed image processing software, the screen uniformity is good, image recognition accuracy is high, clear and fast to complete the defect identification.

For more visual inspection requirements, please contact Pomeas for your selection and solution.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com