With the popularity of optical applications, the demand for production of optical lenses continues to grow, and the increasing maturity of lens technology has facilitated the mass production of optical lenses. The development and production of lenses is very critical to the quality of optical products, so the quality of lenses needs to be controlled.

Inspection needs:

Measure the diameter, true roundness and other dimensions of optical lenses, and automatically determine whether they are qualified or not.

POMEAS can provide dimensional inspection solutions for optical lenses to ensure that the product meets the requirements of the target market and complies with the appropriate standards.

Inspection Solution:

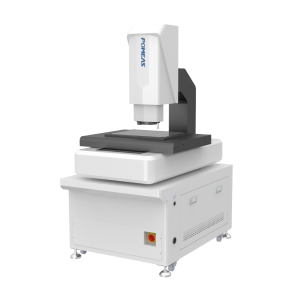

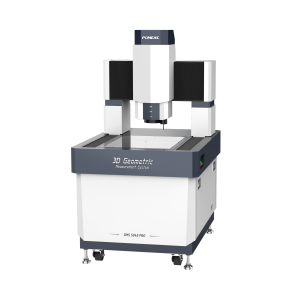

Using the POMEAS IMAGE3 image measuring instrument, a one-click flash measurement can be used to automatically and efficiently complete the lens dimensional inspection.

Advantages of the POMEAS IMAGE3 image measuring instrument:

1. Wide measuring range: meets the needs of different lens sizes;

2. fast measurement speed: one button start, one time can complete the product multiple dimensional characteristics of the measurement;

3. High measurement accuracy: measurement accuracy ±2μm, automatic detection, high repeatability, repeated measurements of the same product can maintain a high degree of consistency;

4. easy to understand the operation: the product interface is clear and intuitive, easy to get started and operate, stable and reliable equipment performance. Data report to adapt to a variety of formats to export, easy to save view.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com