What Are The Items That Are Tested By Image Measurement Vision Solutions?

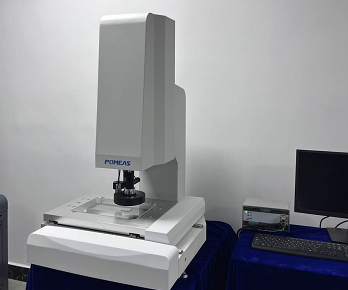

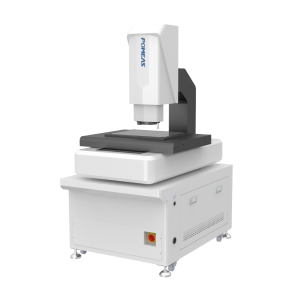

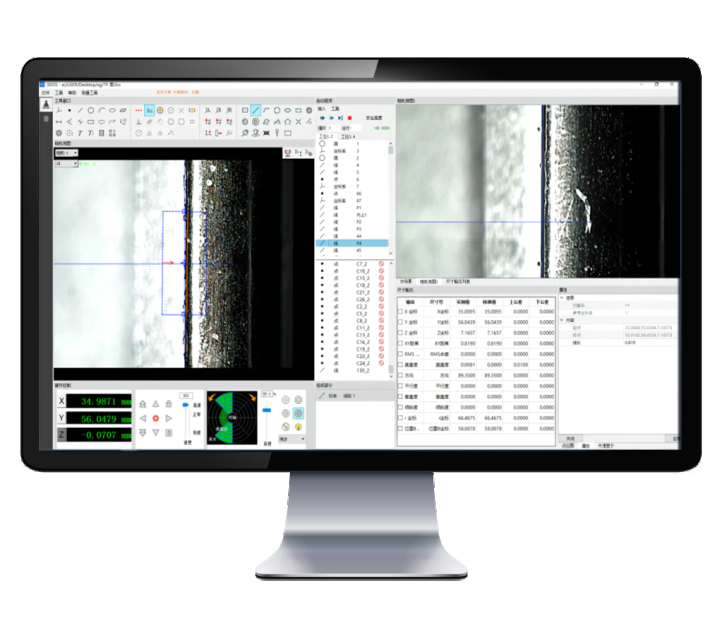

POMEAS Image Measurement Vision Solution is a non-contact measurement solution equipped with self-developed optical modules, spectral sensors and 3DOS measurement software, which can effectively and accurately obtain key information such as geometric dimensions, shape and position of objects.

In addition to the common two-dimensional size inspection, image measurement vision solution can also be flatness, contour, segment difference and other three-dimensional size inspection, for industrial production to provide a more comprehensive quality control means.

Ⅰ.flat size inspection

Image measuring vision solutions have high precision and reliability in flat size inspection. Through high-precision image processing technology, the length, width, diameter and other dimensions of an object can be accurately measured. This information has a significant impact on the consistency of the product. For example, in the production of electronic components, accurate component dimensions are a key factor in ensuring their functionality and stability.

II. Flatness Inspection

Flatness inspection is an important indicator for assessing the flatness of an object's surface. Through image measurement vision solutions, the surface of an object can be compared with an ideal plane and the error in surface flatness can be calculated. This has an important impact on the smoothness and gloss of the product surface, such as glass products, metal plates, etc.

Ⅲ. the contour degree detection

Contour degree detection is a key indicator for assessing the accuracy of the shape of the object's contour. Image measurement vision solutions can calculate the deviation by acquiring the contour image of the object surface. It can provide the basis for shape control and correction in the production process, and improve production efficiency and quality.

IV. Segment Difference Detection

In the production process, the size of the segment difference between adjacent parts directly affects the accuracy and stability of the product fit. Image measurement vision programme can be obtained by acquiring the image of adjacent parts, calculate the positional relationship between them and the height difference. For example, in the manufacture of automotive components, accurate segment difference detection is essential to ensure the safety and performance of the vehicle.

Image measuring vision solutions offer rich functionality and many advantages in inspection projects, with comprehensive coverage from 2D to 3D dimensions, providing strong support for quality control in industrial production processes.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com