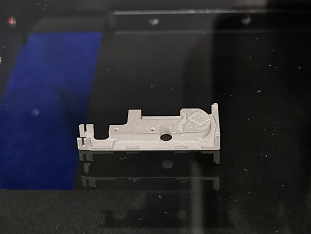

With the rapid development of manufacturing industry, plastic parts are widely used in various products and equipment. As plastic parts are lightweight, low-cost and easy to process, they are widely used in automotive, electronics, medical and other fields. However, since the size and shape of plastic parts are easily affected by factors such as material, process and environment, an efficient and accurate inspection method is needed to ensure that their quality and performance meet the requirements.

Optical vision inspection system is a non-contact, high-precision inspection method based on the optical principle, which can capture the image of the object under test and convert it into a digital signal for processing and analysis. In plastic parts inspection, optical vision inspection system can be used to measure parameters such as size, shape and surface defects. As an optical component in the inspection system, the zoom lens can play many important roles in plastic parts inspection.

The zoom lens has the following applications in plastic parts inspection:

1. Adjustment of magnification: Due to the different sizes and shapes of plastic parts, the magnification needs to be adjusted to fit parts of different sizes. By using the zoom lens, the magnification can be easily adjusted to obtain the best image quality and measurement accuracy.

2. Surface defect detection: Plastic parts surface defects such as scratches, stains, cracks, etc. will directly affect its quality and performance. By using a zoom lens, surface details and defects can be captured and measured and analysed with high precision to ensure product quality meets requirements.

3. Automated inspection: with the continuous development of automation technology, automated inspection has become the main trend of plastic parts inspection. By combining the zoom lens with automation equipment, it can achieve fast and accurate inspection of plastic parts size, improve production efficiency and reduce costs.

Pomeas zoom lens with manual zoom, electric zoom, 4K zoom lens and other models, according to the needs of the optional lens models to meet the requirements of different inspection scenarios.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com