What Is The Difference Between Spectral Confocal Sensors and Line Laser Displacement Sensors?

Sensors play an important role in automated production and quality control, among which spectral confocal sensors and line laser displacement sensors are two common sensor types.They differ in measurement principles and application scenarios.

1. Measurement principle

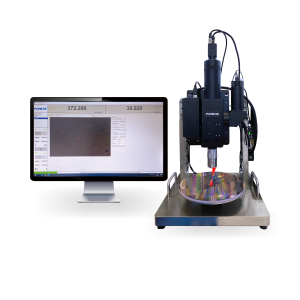

Spectral confocal sensor: Obtains spectral information of surface reflected light by scanning the surface of the measured object to achieve high-precision object surface profile measurement.

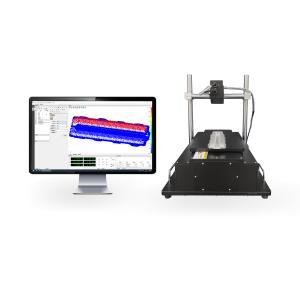

Line laser displacement sensor: Utilizes the principle of laser reflection to obtain the contour information of the object surface by measuring the angle between the beam reflected on the surface of the measured object and the reference beam. The reflection angle is related to the shape of the object surface, so by analyzing the reflection angle, the contour of the object surface can be accurately measured.

2. Application scenarios

Spectral confocal sensor: suitable for high-precision, high-resolution measurement, and can measure transparent, opaque or translucent materials.The spectral confocal sensor has high precision and high resolution, and can achieve micron-level measurements. It has strong adaptability to ambient light and temperature changes.

Line laser displacement sensor: suitable for measuring highly reflective surfaces, such as metal, glass, etc. Since its reflection angle is closely related to the shape of the object surface, the measurement results may not be ideal for surfaces with low reflectivity, such as rubber, wood, etc.

In summary, there are obvious differences between spectral confocal sensors and laser displacement sensors in terms of measurement principles and application scenarios. Depending on the specific measurement needs and application scenarios, the appropriate sensor type can be selected to achieve accurate measurements.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com