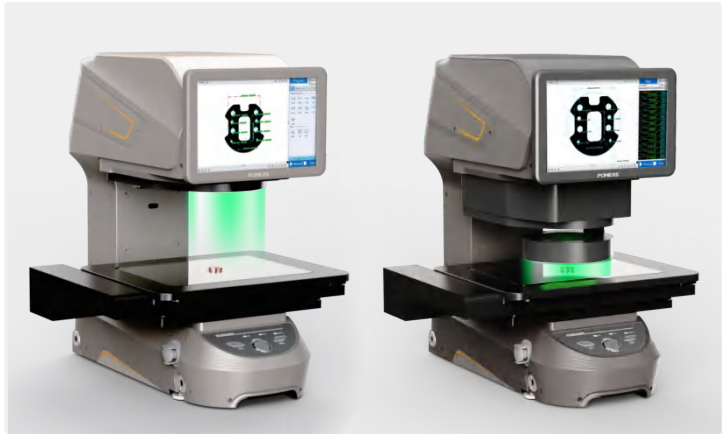

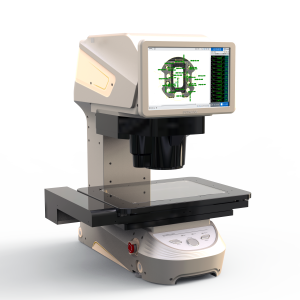

The POMEAS image measuring instrument IMAGE3 series uses a bi-telecentric lens for overall imaging, combines a high-resolution industrial camera with a high-precision image analysis and processing algorithm, and achieves measurement through software calculations. It is a high-precision dimensional measurement system that can achieve rapid measurement of one botton.

The image measuring instrument has the advantages of automatic detection, efficient measurement, automatic focusing, clear and intuitive data, etc., and has various models to meet the detection needs of different customers.

POMEAS image measuring instruments are available in the following models:

1. IMAGE3: Measuring range φ100, measurement accuracy ±2μm, suitable for dimensional inspection of small precision parts. Such as: watch cover, screws, etc.

2. IMAGE3 plus and IMAGE3 pro: equipped with a mobile platform, larger measurement range, measurement accuracy of ±2+L/150μm and ±3+L/150μm, which can be used for larger workpiece size inspection and simultaneous measurement of multiple products. Such as: PCB puzzle boards, motor parts, mobile phone glass, etc.

3. IMAGE3 MAX: Not only does it have a mobile platform, it is also equipped with a self-developed spectrum sensor. In addition to measuring plane dimensions such as angle, length and width, distance, and diameter, it can also complete 3D dimension detection such as height, flatness, and thickness. Suitable for customers with a variety of testing needs, such as mobile phone mid-frame testing, auto parts testing, etc.

The various models of POMEAS image measuring instruments provide different measurement advantages. The appropriate measuring instrument model can be selected according to specific measurement needs and product features.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com