Five Parameters You Need to Know When Choosing A Line Laser Displacement Sensor

Line laser displacement sensor is a commonly used measuring equipment in the industrial field. It adopts the laser triangular reflection measurement principle and can achieve high-precision, non-contact and high-speed measurement of the object surface, providing important convenience for industrial detection.When selecting a line laser displacement sensor, multiple parameters need to be considered based on actual application requirements to ensure that the selected sensor can meet the measurement requirements. This article will introduce five parameters you need to know when selecting a line laser displacement sensor.

1. Measuring range: refers to the maximum and minimum distance that the line laser displacement sensor can measure. When selecting a sensor, you need to select a sensor with a suitable measurement range based on the size of the object being measured and the measurement accuracy requirements.

2. Resolution: refers to the minimum displacement change that the line laser displacement sensor can measure. High-resolution sensors provide greater measurement accuracy, but also increase the cost and complexity of the sensor. Choosing the appropriate resolution should be weighed against actual measurement needs.

3. Repeat accuracy: refers to the error range of the sensor’s measurement results when it repeatedly measures the same position multiple times. It reflects the consistency and reliability of the measurement results when the sensor repeatedly measures the same position in a stable state. When selecting a sensor, you need to choose a sensor with sufficient accuracy requirements to ensure the reliability of the measurement results.

4. Linear accuracy: refers to the deviation range between the displacement of the object measured by the sensor and the true displacement of the object. This indicator is useful when measuring a relatively large height difference and hoping to focus on the true absolute height difference.

5. Sampling frequency: refers to the number of measurements per second by the line laser displacement sensor. The higher the frequency, the shorter the measurement time, and the more suitable it is for measuring high-speed moving objects.

Choosing a suitable line laser displacement sensor is of great significance for industrial production detection.When selecting a sensor, you need to comprehensively consider parameter requirements such as measurement range, resolution, accuracy, and sampling frequency, as well as requirements such as environmental adaptability, stability, and reliability. At the same time, it is also very important to choose a sensor supplier with good after-sales service and technical support capabilities.

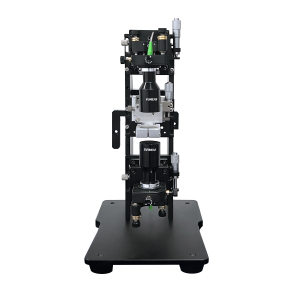

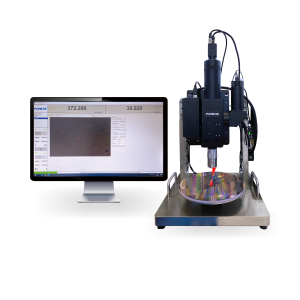

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com