Advantages of Spectral Confocal Sensors for Measuring Free Form Surfaces

Free-form surface refers to a surface whose surface shape cannot be continuously processed and has the arbitrary characteristics of traditional processing and molding. Due to their improved functionality and new production methods, free-form surface components are increasingly used in optics, automotive, electronics and other fields. In order to ensure the overall quality of the product, it needs to undergo strict appearance inspection.

There are two methods for component appearance inspection: contact measurement and non-contact measurement. Contact surface measurement may cause scratches and reduce component quality, so non-contact measurement is more suitable for surface inspection of free-form components.

Spectral confocal sensor is a "point" high-resolution and ultra-high-precision non-contact sensor. For the measurement of free-form surface components, the spectral confocal sensor can achieve high-precision measurement of free-form surface components through simple operations. Its advantages are mainly reflected in the following three aspects:

1. High accuracy: Since the measurement process is non-contact, it will not cause damage to the components, and also avoids possible errors in contact measurement;

2. Fast measurement speed: the measurement speed can reach hundreds of points per second, and changes in surface shape can be monitored in real time;

3. High practicability: Spectral confocal sensors can be applied to different types of free-form surface components, including aspherical surfaces, free-form surface prisms, etc.

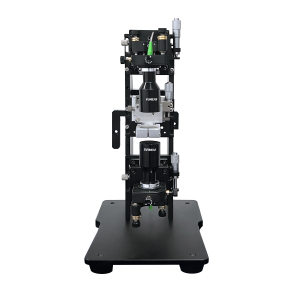

POMEAS spectral confocal sensor has the advantages of non-contact, high precision and high sensitivity. It not only has broad application prospects in measuring free-form surface components, but is also an important tool in the manufacturing and testing of industrial parts.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com