Laser profile sensor is a non-contact measurement sensor that uses a semiconductor laser light source to illuminate the measured object's surface to obtain corresponding data information, which can achieve high-precision size detection and visual positioning. Laser profile sensors have many advantages and are suitable for automated production lines, semiconductor manufacturing, automobile manufacturing, mobile phone manufacturing, aerospace, medical equipment, and other fields. The specific advantages of laser profile sensors are as follows:

1. High precision: It can achieve high-precision contour measurement, especially when the contour shape is complex or high-precision positioning is required, the advantages are more obvious.

2. Non-contact: The laser profile sensor adopts non-contact measurement, which can avoid measurement errors caused by friction, gaps, and other factors in traditional contact measurement methods, and eliminate the influence of human interference factors.

3. High speed: The laser profile sensor has high-speed characteristics and can complete a large number of profile scanning measurements in a short time, making it suitable for rapid inspection on large-scale production lines.

4. High repeatability: The laser profile sensor has high repeatability accuracy, which can ensure the accuracy of measurement and reduce the accumulation of measurement errors.

5. High applicability: The laser profile sensor is suitable for various measurement occasions. It can perform profile measurements on workpieces of different materials and sizes and has strong applicability.

Laser profile sensors are widely used in industrial detection. They can improve measurement accuracy and efficiency and ensure product quality and consistency. They are one of the indispensable and important detection methods in modern industrial production.

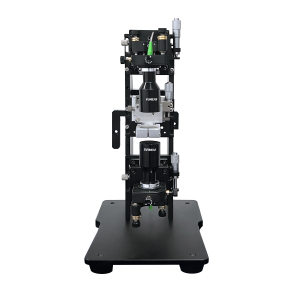

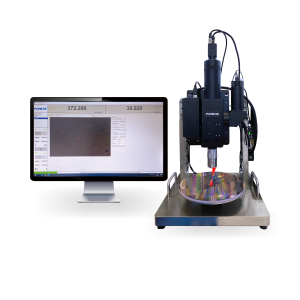

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com