The composition of an automobile contains countless parts, each of which is very important. Therefore, there is a need for good information traceability and quality inspection of each component in automobile manufacturing.

POMEAS is a machine vision and industrial automation core product suppliers, can provide automated automotive parts vision solution needs to be used in the lens, camera, light source, software recognition system, etc., this article introduces the clutch flywheel detection configuration solution.

The flywheel is the main workpiece of the clutch. During the assembly process, it is usually necessary to complete tests for the absence of springs and ball rollers inside the clutch, as well as for the correct mounting position.

Detection Solution:

1. Lenses using POMEAS bilateral double-magnification telecentric industrial lenses;

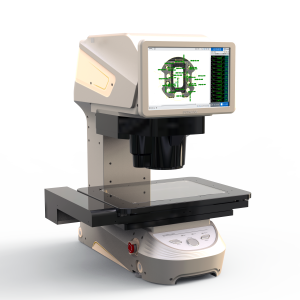

2. Camera using POMEAS 5 MP high frame rate industrial camera;

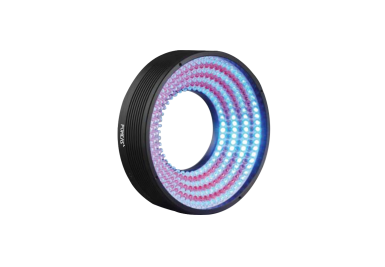

3. With ring vision light source and POMEAS independently developed vision inspection system.

Detection Effect Diagram:

Solution Advantage:

Clutch flywheel size is large, using dual telecentric industrial lenses, with large depth of field, high resolution, low distortion and other advantages, with ring vision light source, can emphasize the internal image of the clutch, and accurately complete the visual inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION