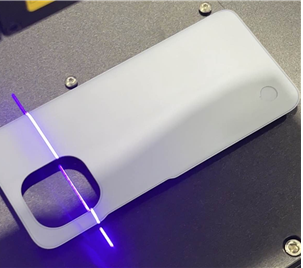

Smart phones are the 3C products with the largest market share, and the huge market share has created white-hot competition among cell phone manufacturers, and the design of cell phone shells, screens and other accessories tends to be diversified.Cell phone shell is an important part of the composition of the phone, quality testing requirements are also very strict.

Detecting Difficulties:

Cell phone backshells are curved, and measurements include flatness, contour, etc. Traditional inspection techniques are difficult to meet the demand.

Detection Solution:

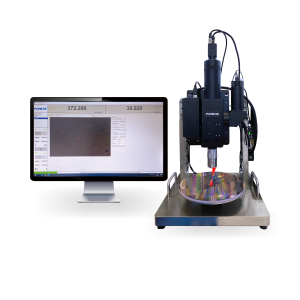

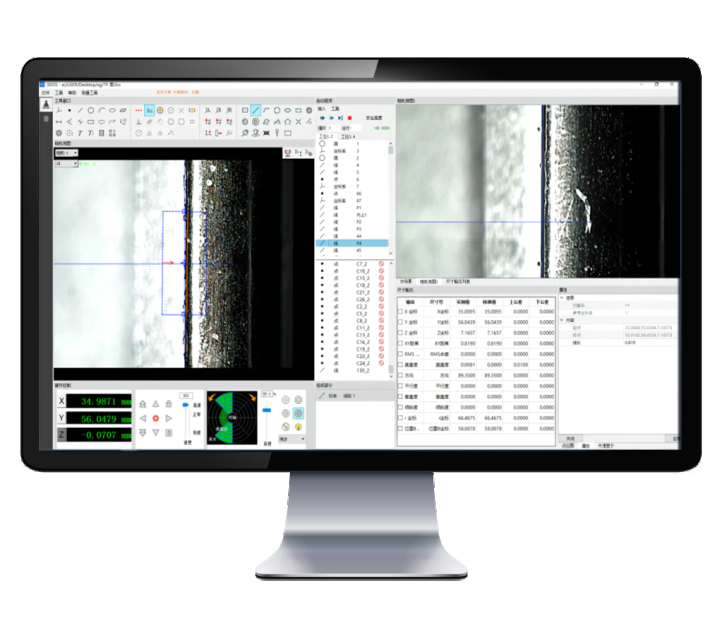

Adoption of POMEAS self-developed line laser sensor with 3DOS measurement system,to do 3D data acquisition and comparison of measurement analysis, scanning the back of the cell phone shell point cloud data and standard documents for comparison, according to the parameters of the color gradient to determine the deviation value of the contour, and directly control whether the product size is in line with the requirements.

Program Advantages:

1. Detection speed can be achieved within 10s, suitable for production line high-volume product inspection.

2. Measurement accuracy can reach ±3μm, high measurement precision.

3. non-contact detection, to avoid errors due to contact with the surface of the workpiece.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

3D SCAN SYSTEM

APO laser auto-focus module --motor

3DOS-H VISION SYSTEM

Line Laser Displacement Sensor

3DOS vision system

PMS-LFS SERIES

3D GMS Pro

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

- APPICATION CASE

- RESOURCE CENTER

- DOWNLOAD CENTER

SOLUTIONS SUPPORT

- ZOOM LENS SELECTION TOOL

- TELECENTRIC LENS SELECTION TOOL

- FA LENS SELECTION TOOL

- ZOOM RATIO TABLE

- CERTIFIED MODEL

SELECTION TOOL

- WHY POMEAS

- FAQ

- PRIVACY POLICY

- TERMS OF USE

- DELIVERY & RETURN POLICY

CUSTOMER CARE

ADDRESS

ADDRESS

Add.:No.68, Chongwei Road, Baizhoubian, East district, Dongguan, China, 523000

CONTACT

Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867

E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com

Wechat QR code

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION