Aluminum products are common spare parts in industrial production, due to the production process, some products will be deformed and other problems, errors in assembly. In order to ensure the quality of the product, it is necessary to do a good job of quality inspection.

Detection Requirements:

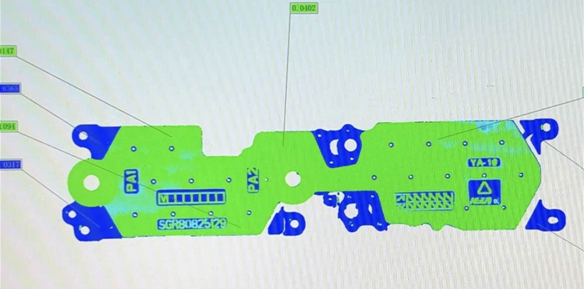

Detects flatness parameters on the top of aluminum products and identifies surface characters for misprints, omissions, reverse prints and other defects.

Detection Solution:

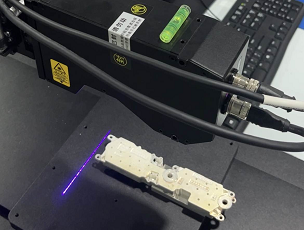

Using POMEAS line laser sensor with 3D OS measurement software, scanning the product surface data, compared with the standard file for analysis, you can clearly see the value of the flatness of aluminum products, and efficiently identify product character defects.

Program Advantages:

1. The line laser sensor is stable, adaptable and has high detection accuracy.

2. 3DOS measurement software can quickly scan and analyze the measurement data, simplifying the measurement process.

3. Non-contact measurement, the inspection system is not interfered by the workpiece surface material, color and on-site environment, and the measurement error is small.

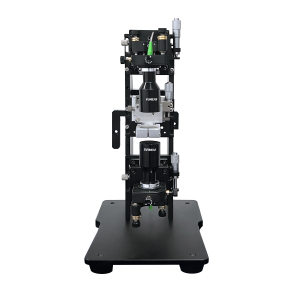

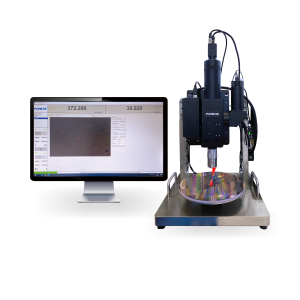

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com