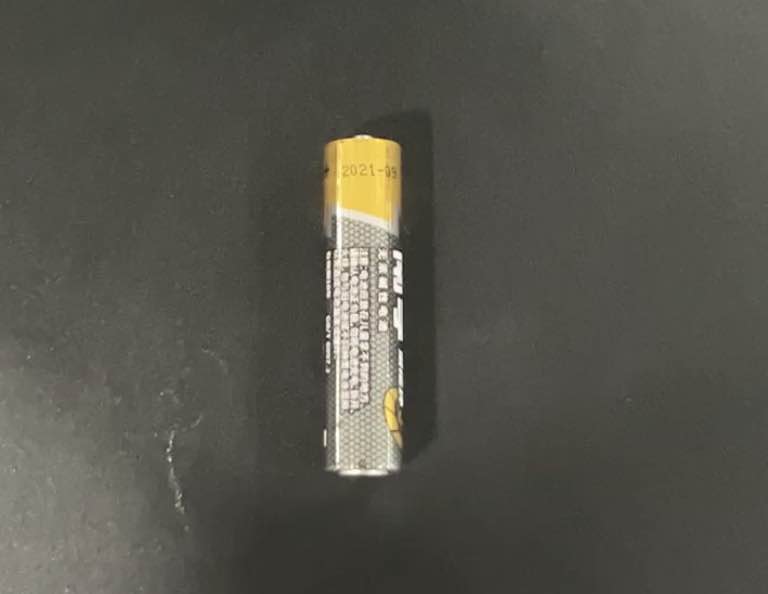

Batteries play a big role in our daily life, and they are found in various remote controls, electric toys, and electronic products.

When the battery is manufactured, various characters will be printed on the surface to let the user clearly understand its brand, performance, production and use information and other parameters.In the actual screen printing printing process, the characters on the surface of the battery will also have the appearance of quality problems, in order to ensure that defective products will not enter the market, you need to do a good job of quality inspection.

Detection Requirements:

Detect whether there are defects such as misprints, omissions, missing characters and surface scratches on the battery surface.

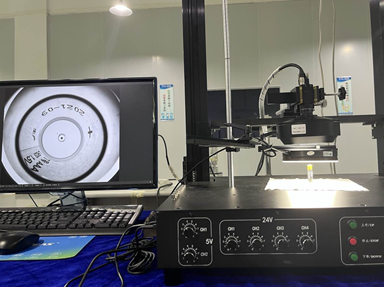

The common solution is to use vision detection systems,Batteries are cylindrical, requiring multiple industrial cameras and lenses to shoot from different sides, and then synthesize and identify the images for determination, so is there a solution that uses a camera and can be able to shoot the complete battery surface characters?

Solution:

With the POMEAS 360° outer wall inspection lens, only one camera and lens are needed to present a complete image of the outside of the battery ring, clearly identifying all defects, effectively simplifying the layout of the vision system and reducing costs.

POMEAS is committed to the manufacturing plant industrial vision inspection intelligence, can provide complete vision solutions and core accessories, if you have the corresponding needs, you can contact us.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com