With the development of technology, the size of the IC chip is getting smaller and smaller, the complexity is also increasing, for the quality control is also becoming more and more stringent, weld joint inspection is one of the important part.

Detection Requirements:

Detect whether the surface of the weld joint is continuous and smooth without excessive brightness, identify whether there are defects on the surface such as leakage, false welding, adhesion, etc., and determine whether the weld joints are correctly positioned.

The traditional detection method is to conduct visual inspection manually, but the detection is susceptible to human subjective influence, and the error is large.With the development of industrial automation, it has been gradually replaced by machine vision inspection.

Machine vision systems use a combination of industrial cameras plus lenses, light sources,under different colors of light, any weld can be clearly imaged, with the software for automatic identification and detection, which greatly improves the efficiency and quality of weld joint inspection.

Detection Solution:

1. Lens using POMEAS 4K zoom lens PMS-K75 series, 4K-class high-resolution imaging, you can obtain high-quality images of the weld joints to enhance the detection capabilities.

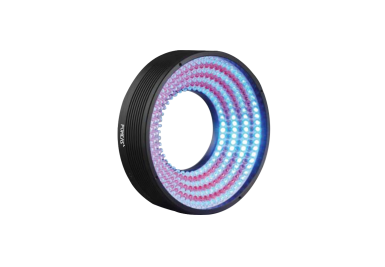

2. With POMEAS Gigabit network industrial camera and ring light source, the defects of weld joints can be clearly presented to improve the inspection efficiency.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com