There are tens of thousands of parts in automotive manufacturing, and the performance of each part can affect the quality of the vehicle.In order to measure whether the automotive parts meet the delivery standards and requirements, it is necessary to do a good job of strict quality control.

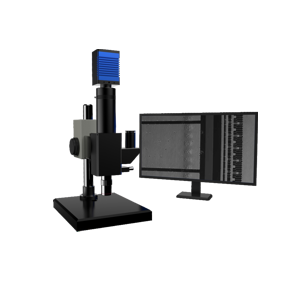

3D video microscope has the advantages of large depth of field range, high resolution, high contrast, real-time image observation, 360 ° rotating mirror, all-around observation effect, and so on.High-quality images and highly reliable results can be obtained in automotive parts inspection.

Applications in automotive parts inspection:

1. Observe the filter foreign matter: fiber is a complex structure, the whole is difficult to focus, easy to cause halo.Using 3D video microscope with high contrast images and vibrant colors, you can get sharp images;With the depth-of-field extension function, you can quickly acquire an image of the full focal plane.

2. Observation of gear parts: It is easy to cause halos characteristic of metal materials, and it is difficult to observe the shape of the entire sample.3D video microscope gives sharp images. The 3D observation function makes it simple to acquire a realistic sample shape.

3. Observation of spark plug wear state: Magnified observation of the product can only be partially focused, making it difficult to acquire the shape.With 360° rotating mirror observation, samples can be inspected from all angles and all-around images can be acquired.

3D video microscope has a wide range of applications in the automotive parts industry, and is an important microscopic observation tool for quality assurance and product development in the automotive industry.It not only detects, measures and analyzes, and outputs report results, but also makes this testing work easier, faster, simpler and more reliable!

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com