Measuring Dimensions of Precision Stamped Parts with Image Measurement Instruments

Precision stamped parts are the basis of industrial production, only strict control can ensure the quality of the final product.

Detection Requirements:

Efficiently completes dimensional measurements such as length, width, circle-circle distance, hole diameter, angle, etc. of stamped parts.

Measurement Difficulties:

The traditional inspection program is to use calipers or manual imaging instrument, low inspection efficiency, affecting production capacity, manual measurement will be brought into the measurement error, measurement accuracy is not high, and labor costs are high, increasing business operating costs.

Solution:

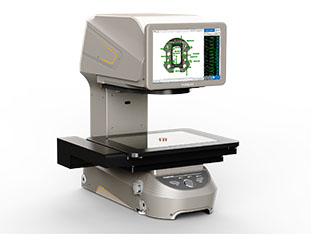

IMAGE3 Image Measurement Instrument can solve the problems of traditional inspection methods, and can measure multiple stamped parts simultaneously at one time, which effectively improves the inspection efficiency and reduces the operation cost. The measurement process is fully automated, with no manual errors and high measurement accuracy.

To use the image measurement instrument, you only need to place the stamped part product on the equipment load table, program the required measurement part, and then start the run button, the measurement can be completed in a few seconds, the result will be produced automatically, and the tolerance determination will be completed, the data is accurate and intuitive, and the measurement process is simple and easy to understand.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com