How to Improve Dimensional Measurement Efficiency in Industrial Inspection

Industrial inspection is an important means of quality control in industrial production, which usually includes items such as appearance image recognition, dimension measurement, and vision positioning.

Dimension measurement is one of the most basic and important control elements, which is one of the most important conditions to ensure product quality.There are various kinds of instruments used for dimensional measurement in the market today, such as micrometers, calipers, image meters, etc.. However, these instruments can cause the following problems during the measurement process:

1. When measuring multiple workpieces, you need to inspect them one by one, and the inspection time is long;

2. Susceptible to the subjective influence of personnel, change the operation of different staff, there will be different measurement data and results;

3. The operation process is complicated and time-consuming;

4. Data statistics management is relatively cumbersome.

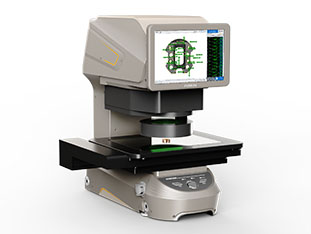

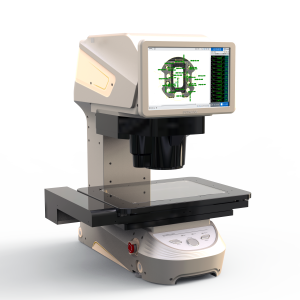

POMEAS IMAGE3 image measurement instrument can well solve the above difficulties and improve the efficiency of dimensional measurement. The main advantages of this instrument are as follows:

1. The image measurement instrument has a large measuring range and can be used for batch inspection, multiple measurement objects, and image acquisition, size measurement and tolerance evaluation can be completed in a few seconds, which effectively improves the measurement efficiency.

2. The image measurement instrument has an automatic positioning function, and the position of the product can be placed at random when measuring.

3. Simple structure, excellent stability, no need to move the worktable during the measurement.

4. The image measurement instrument can simultaneously perform optical inspection and data analysis on the product contour, the whole process is automated, and there is no human operation causes data differences.

5. The operation interface is simple and easy to use, without spending too much time on personnel training.

6. The image measurement instrument is equipped with a high-resolution telecentric industrial lens and high-precision algorithm analysis, the measurement data is quite accurate.

Currently image measurement instruments are widely used in precision electronics, PCB boards, cell phones, aerospace, molds, medical machinery, automotive engineering, cutting tools and other industries.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com