Practical applications of industrial vision inspection systemsPractical applications of industrial v

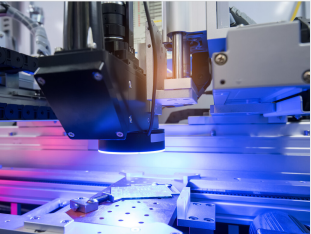

In industrial production, there will always be some defective products, the traditional method is to screen manually with naked eyes to eliminate the defective products and ensure the quality of the products. However, manual inspection is inefficient and may also bring some unsafe factors, with the development of technology, industrial vision inspection system is widely used to overcome the shortcomings of the traditional manual inspection, with high automation, safety and reliability, high accuracy and other advantages. What are the specific applications of industrial vision inspection system? This article introduces some cases to understand.

1. Battery surface defects detection: in the battery production process, may be caused by the processing process of the product surface foreign matter, appearance of scratches, stains, sealing foreign matter, indentation, wrinkles, depressions, bumps and other defects, these defects will cause potential hazards to the use of the product, the use of visual inspection system, can quickly and efficiently eliminate defective products, complete quality inspection.

2. PCB circuit board inspection: PCB boards in a number of industries have applications, the quality requirements are more stringent, the use of industrial vision inspection system can complete the product dimensions measurement and weld joints, missing components, PIN pins and other surface defects detection.

3. Precision parts detection: with the progress of manufacturing and processing capabilities, the development of precision parts is also accelerating, in order to protect the production efficiency and quality of precision parts, visual inspection is essential, this type of inspection has entered the microscopic range, many defects can no longer be seen by the human eye, can only be achieved through automated means of detection, industrial vision inspection can be done is the size of the parts detection, as well as Products appearance scratches, damage detection.

4. Visual recognition: In areas such as food packaging, we need to capture key information such as barcodes, production dates, shelf life, etc. on the product line, which can also be done by these industrial vision inspection systems.

In addition, industrial vision inspection system has a wide range of applications in the mobile phone, automotive, glass and other industries.POMEAS is a supplier of core products for industrial vision inspection system, with products such as zoom lenses, telecentric lenses, FA lenses, image dimension meters, industrial microscopes, spectral sensors, etc., and we can provide core vision system accessories and complete set-up solutions.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com