With the development of science and technology, new energy vehicles are accepted by more and more consumers, and more and more figures in life. The favorable policies for new energy vehicles and the soaring oil prices have also attracted many oil vehicle users to the field of new energy vehicle consumption.

The battery system of new energy vehicles is an important part of new energy vehicles, mainly composed of battery modules, electrical systems, thermal management systems, casings and cover plates. The battery cover plate can protect the battery from being damaged when it is impacted or squeezed by the outside world. Therefore, the required process is very strict, and precise quality control is required. This article introduces the flatness detection scheme of the battery cover.

Testing requirements:

Fast and efficient detection of the flatness of the new energy battery cover, the tolerance requirement is 0.3mm.

Detection scheme:

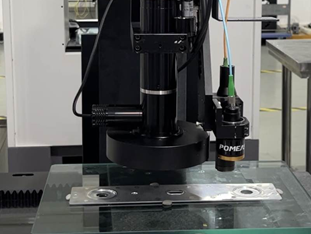

Using POMEAS 8055 spectral confocal sensor solution, non-contact measurement, compared with the traditional contact measurement method, it can avoid the occurrence of foreign objects and appearance wear on the product, and can accurately identify the flatness of the battery cover, and the measurement speed is fast, 10 seconds. The detection can be completed; the measurement results are stable and the tolerances meet customer requirements.

POMEAS has been deeply involved in the field of industrial visual inspection for many years. Its main products include industrial lenses, industrial cameras, visual light sources, video microscopes, spectral sensors, image measuring instruments, etc. It can provide complete vision solutions and optical accessories for precision inspection fields such as visual inspection and dimensional measurement. .

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com