Industrial telecentric lenses are widely used in some machine vision inspections that require fast execution and repeatability and high measurement capabilities. This article introduces the advantages and applications of industrial telecentric lenses in detail, so as to understand how telecentric lenses affect the performance of the vision system.

Advantages of Industrial Telecentric Lenses

1. High resolution

Image resolution is generally measured by the CTF (contrast transfer function) that quantifies the contrast between the existing spatial frequencies of the image sensor. Most machine vision integrators tend to just aggregate a lot of cheap low-pixel, low-resolution lenses, and end up producing only blurry images. With industrial telecentric lenses, even with small pixel image sensors, high-resolution images can be generated.

2. Low distortion

The distortion coefficient is the percentage difference between the actual size and the image size of the image sensor. Ordinary industrial lenses usually have distortion higher than 1~2%, which may seriously affect the accuracy of the measurement. In contrast, industrial telecentric lenses pass strict manufacturing and quality inspection, and this error is strictly controlled below 0.1%.

3. No perspective error

When making precise linear measurements in metrology applications, it is often necessary to observe from the standard front of the object. In addition, many mechanical parts cannot be placed precisely, and the measurement time interval is constantly changing. It is not possible to obtain an exact image of the real object. Because the entrance pupil of the industrial telecentric lens can be located at infinity, it can only receive the main ray parallel to the optical axis during imaging, which can perfectly solve the above confusion.

4. Ultra-wide depth of field

The double telecentric industrial lens can not only use the aperture and magnification to enhance the natural depth of field, but also has the unparalleled optical effect of the non-telecentric lens: the image remains unchanged when the object is moved within a certain object distance range, that is, the magnification remains unchanged.

Application of industrial telecentric lens

1. Inductive hexahedron defect detection: The use of Purmis constant F5 large aperture zoom telecentric lens can ensure high magnification light flux, accurately identify defects, and improve detection accuracy.

2. Dimensional measurement of reflective metal parts: When the reflective metal parts are detected, the external light source will have irregular reflections in the metal edge area, and each point of the edge contour will form a diffuse reflection point, so that the contour boundary will form a grayscale transition zone , the accuracy of contour extraction cannot be guaranteed. The industrial telecentric lens adopts special optical design, which can effectively avoid the effects of various stray reflections, greatly improve the sharpness of the edge of the picture, solve the problem of reflection at the edge of metal parts, and improve the measurement accuracy.

The industrial telecentric lens can also be used in the detection of hardware, mobile phone parts, mobile phone glass, auto parts and other high-precision products. For more cases, you can consult POMEAS to provide you with a complete solution.

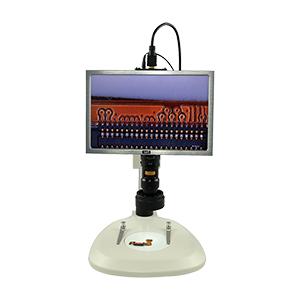

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com