PCB connector is a connecting device used to connect and fix printed circuit boards to realize the connection between circuits. The quality of the connector directly affects the quality of the finished product, and in the face of small defects on the connector, it is invisible to the naked eye. A mistake will have a serious impact on other parts and products, so in the manufacturing process, real-time inspection of all aspects of the connector is very important.

In the process of producing PCB soldered connector products, defects such as PIN pin offset, missing, solder connection short circuit, virtual soldering, tin connection, and de-soldering open circuit are prone to occur. What kind of equipment can be used to detect these defects in real time and quickly and eliminate defective products?

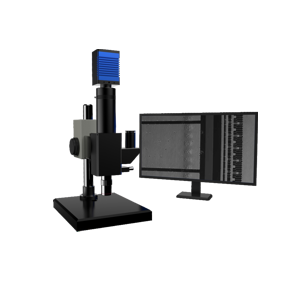

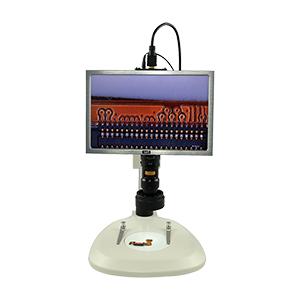

POMEAS auto-focus video microscope can realize on-site inspection, has high zoom ratio, and has good parfocality when zooming, and is equipped with an auto-focus industrial camera with built-in high-definition photosensitive chip and high-speed processor, which can automatically identify focus information and obtain it instantly. High-definition images make viewing of connector pins more efficient.

The POMEAS autofocus video microscope can also take photos, videos, save, and archive the inspection results of the pins for later repair or replacement. Thereby greatly increasing the inspection work efficiency and reducing manpower and material resources.

POMEAS video microscope provides real ease of use, efficient and convenient operation, enabling users to obtain high-efficiency and low-cost quality inspection solutions in the development and manufacturing of electronic products.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com