With the expansion of enterprise scale and output, it has great application advantages to use machine vision system to replace people to complete the production and quality inspection. In view of this application requirement of the enterprise, POMEAS has launched a series of solutions for different industries to apply visual inspection technology.

Application of Electronic Manufacturing Industry

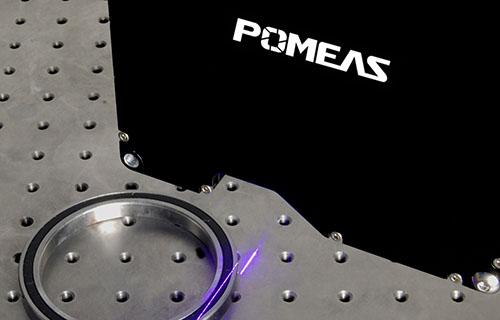

In recent years, due to the miniaturization of electronic assembly, the production process of products requires higher requirements, but the output is increasing. It is impossible to ensure the quality and efficiency of the production line only by human eyes in the process of circuit board assembly and electronic product assembly. Machine vision technology is replacing human beings for fully automatic products. Detection and process validation, such as assembly clearance detection, can be realized by using laser profile sensor.

Application of Laser Profile Sensor--Gap Measurement of Parts Assembly

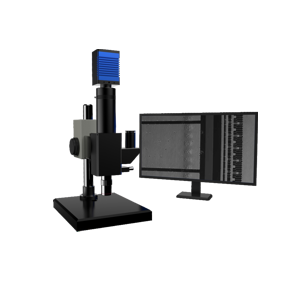

The advantages of visual detection technology over artificial naked eye detection are obvious. Comparing with human eyes, machine vision inspection is not only fatigue-free, but also has the consistency and repeatability that human beings do not possess. POMEAS high-definition video microscope can magnify the surface details of products through high-precision cameras, take pictures and analyze them at a fine level, and detect quality problems that human eyes can not find, such as PCB board defects. Mobile phone parts defects, liquid crystal defects, wafer defects, optical lens defects, etc.

Application of Video Microscope--Solder Joint Detection

Application of Automobile Manufacturing Industry

With the continuous improvement of automobile industry automation level, some traditional detection methods can not meet the needs of high-tempo, flexible production. Machine vision online detection technology with real-time monitoring function has gradually been applied in mainstream manufacturers, and achieved good results.

In the automatic automobile production line, the vision system needs to match the application with the robot when necessary, and establish a connection with the PLC control system of the production line to realize the functions of measurement, detection, positioning and recognition. The visual inspection system has the following characteristics: adopting non-contact inspection method, improving response speed and little impact on production line; having the performance of long-term stable and reliable repetitive work, it is suitable for continuous assembly line operation of automobiles; it is suitable for working in areas with high safety risk, poor ergonomics and poor environment. Moreover, the accuracy has been greatly improved, and the qualified rate of the products of the enterprise has been improved.

Application of Precision Instrument Industry

Machine vision has attracted extensive attention of enterprises because of its advantages of high detection accuracy and speed and effective avoidance of subjectivity and individual differences caused by manual detection. In the precision manufacturing industry, it has been used to detect scratches and depressions on the surface of precision machined parts. It is an ideal choice to achieve high-quality product production and reduce costs.

The surface quality requirements of precision parts are higher than those of ordinary parts. Smoother surface of parts can improve the wear resistance, corrosion resistance and fatigue resistance of precision instruments. For the detection of precision parts, the quadratic image measuring instrument was used before. With the improvement of precision requirements and measurement speed, POMEAS introduced AI intelligent one-key measuring instrument. It realizes auto-focusing and auto-polishing technology, realizes real intelligent measurement, avoids human error, personal measurement error, one-key measurement and analysis data.

AI Intelligent One-button Measuring Instrument

Comparing with manual quality inspection, machine vision inspection can check product quality more accurately and reduce production cost. It can also work 24 hours uninterruptedly. It can even realize on-line detection in various harsh production environments that are not suitable for human work. The accuracy of detection can be higher than that of manual inspection.

Product recommendation

TECHNICAL SOLUTION

MORE+You may also be interested in the following information

FREE CONSULTING SERVICE

Let’s help you to find the right solution for your project!

ASK POMEAS

ASK POMEAS  PRICE INQUIRY

PRICE INQUIRY  REQUEST DEMO/TEST

REQUEST DEMO/TEST  FREE TRIAL UNIT

FREE TRIAL UNIT  ACCURATE SELECTION

ACCURATE SELECTION  ADDRESS

ADDRESS Tel:+ 86-0769-2266 0867

Tel:+ 86-0769-2266 0867 Fax:+ 86-0769-2266 0867

Fax:+ 86-0769-2266 0867 E-mail:marketing@pomeas.com

E-mail:marketing@pomeas.com